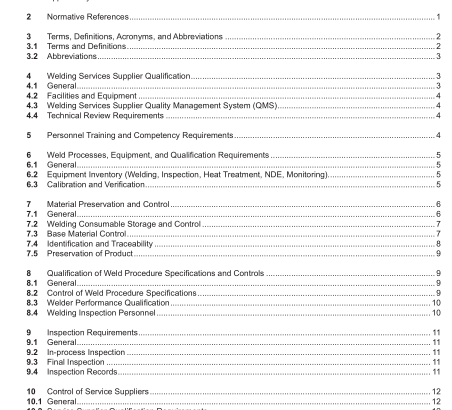

API Std 20G:2020 pdf free download.Welding Services for Equipment Used in the Petroleum and Natural Gas Industry

4.2 Facilities and Equipment

To conform to this standard, the WSS shall have the following capabilities:

— equipment to perform required welding activities;

— a facility to store required equipment and to maintain required documents and retain records;

— appropriate handling and lifting equipment (as applicable); and

— inspection and test equipment (as applicable).

4.3 Welding Services Supplier Quality Management System (QMS)

The WSS shall establish, document, implement, and maintain a QMS and associated processes. The QMS shall be in conformance with this standard and API Specifcation Q1 or ISO 9001. The WSS shall determine the processes needed for the quality management system and their application through all operations.

The WSS shall defne the audit requirements for processes covered by this standard, including welding, weld NDE, and post-weld heat treatment (PWHT) to ensure that these processes achieve planned results. Internal audits shall be performed at least every 12 months, covering all on-site areas and shifts.

4.4 Technical Review Requirements

The WSS shall maintain procedure(s) to ensure that technical requirements are reviewed prior to acceptance of the order.

The WSS shall maintain records of this review, including:

— applicable customer or governing design and construction specifcations/standards;

— material specifcations;

— acceptance criteria for welds;

— qualifcation of welding procedures;

— qualifcation of welding personnel;

— outsourced services;

— inspection and testing requirements, including third-party verifcation;

— identifcation and traceability (see 7.4);

— special welding requirements;

— requirements for use of special methods.

5 Personnel Training and Competency Requirements

Personnel shall be competent to carry out assigned tasks/responsibilities based on the appropriate education,training, skills, and experience needed to meet product and customer requirements. A written procedure shall defne personnel competency and identify training and qualifcation requirements.

The WSS shall identify:

— roles that require familiarity with welding and testing;

— roles that require a knowledge of welding and testing;

— methods required for personnel training qualifcations;

— knowledge and training necessary to address specifc customer requirements;

— qualifcations required for personnel performing processes that require validation;

— method(s) used to verify the competency of personnel.

The WSS shall maintain evidence of conformity to the above requirements.

6 Weld Processes, Equipment, and Qualifcation Requirements

6.1 General

The WSS shall maintain a system of written procedures for each welding support service performed. Welding procedure specifcations (WPS) shall comply with the applicable nationally or internationally recognized standards. The development of a weld practice shall comply with the QMS. Individual(s) other than the person or persons who developed the procedure shall approve the fnal procedure. Changes to procedures shall require the same controls as the original documentation.

6.2 Equipment Inventory (Welding, Inspection, Heat Treatment, NDE, Monitoring) The WSS shall maintain an inventory of all available welding and support equipment, with the following information noted

— name of the manufacturer;

— equipment model and serial number;

— calibration requirements, current software, etc.;

— range of operation and range of calibration;

— traceability of calibration records to a recognized international standard used for calibration;

— frequency of calibration;

— allowable tolerances or maximum sensitivity.

6.3 Calibration and Verifcation

6.3.1 General

Equipment used to inspect, test, or examine material or other equipment shall be identifed, controlled, calibrated, and adjusted at specifed intervals in accordance with documented manufacturer instructions, and consistent with nationally or internationally recognized standards. Records of all calibration shall be maintained.

6.3.2 Measuring and Testing Equipment

The WSS shall maintain a documented procedure to ensure that testing, measurement, and monitoring equipment is calibrated and maintained, and that the equipment is used in a manner that is consistent with monitoring and measurement requirements. Calibration shall conform to and be traceable to nationally or internationally recognized standards, as applicable.

6.3.3 Welding Equipment Welding machines and welding control equipment shall be calibrated as specifed by the manufacturer. The frequency of calibration shall be at least annual. In addition, the following shall be checked during calibration:

— condition of volt meters, amp meters, and gas fow meters (if equipped);

— condition of cables;

— condition of hoses (if equipped);

— condition of wire feeders (if equipped).API Std 20G pdf download.API Std 20G:2020 pdf free download