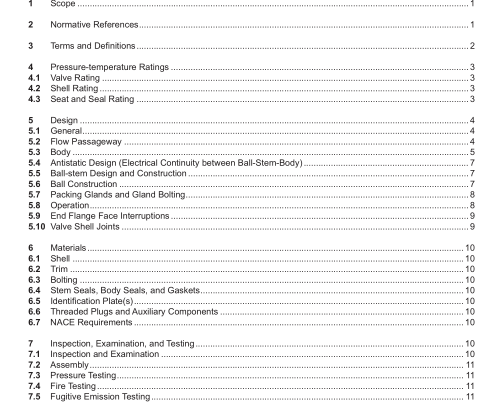

API Std 608:2020 pdf free download.Metal Ball Valves—Flanged, Threaded, and Welding Ends

5.4 Antistatic Design (Electrical Continuity between Ball-Stem-Body) Valves shall incorporate an antistatic feature that ensures electrical continuity between the stem and body of valves ≤ DN 50 (≤ NPS 2) and between the ball, stem, and body of valves > DN 50 (> NPS 2). The antistatic feature shall have electrical continuity across the discharge path with a resistance not exceeding 10 ohms from a power source not exceeding 12 volt direct current (Vdc) when type-tested on a new, dry, as-built valve after open-close position cycling of the valve at least fve times. 5.5 Ball-stem Design and Construction

5.5.1 The valve shall be designed to ensure that if a failure occurs at the stem-to-ball connection or of the stem itself within the pressure boundary, no portion of the stem is ejected by internal pressure.

5.5.2 The stem shall be of an anti-blowout design and stem seal retaining device shall not be the sole means used for stem retention. The design shall ensure the stem cannot be ejected from the valve by disassembly of gland bolting or actuator mounting hardware.

5.5.3 The torsional strength of both the stem-to-ball connection and the portion of the stem within the pressure boundary (below top of packing) shall exceed the torsional strength of the stem portion above the pressure boundary (above the top of the packing) by at least 10 % at the maximum valve rated temperature.

5.5.4 The stem and the ball-to-stem connection shall be designed such that no permanent deformation occurs, and no failure of any part occurs when a force applied to the lever or gear operator handwheel produces a torque equal to the greater of:

— 20 N m (15 ft-lb) or

—twice the manufacturer’s maximum published torque. The manufacturer’s maximum published torque shall be based upon clean, dry air service at the maximum diferential pressure rating of the valve.

5.6 Ball Construction The ball shall have a cylindrical bore and shall be of solid one-piece construction. Other constructions such as “hollow”-type, cored cavity, or sealed cavity may be furnished only if agreed by the purchaser.

5.7 Packing Glands and Gland Bolting

5.7.1 Adjustable packing glands shall be accessible for resealing stem packing without the disassembly of valve parts or operator parts.

5.7.2 Packing glands that are threaded into bodies or covers or onto stems shall not be used for valve sizes greater than DN 80 (NPS 3) unless otherwise specifed by purchase order. (See Figure C.1 and Figure C.2 for parts identifcation.)

5.7.3 Vertically split glands shall not be used.

5.7.4 When used, gland bolts shall pass through holes in the packing gland. The use of open slots is not permitted on any portion of the packing gland.

5.7.5 As a minimum, packing gland bolts shall be designed so that the bolt stress shall not exceed one-third of the ultimate tensile strength of the bolting material when compressing packing material to a compressive stress of 38 MPa (5500 psi) at 38 °C (100 °F).

5.8 Operation

5.8.1 Unless otherwise specifed on the purchase order, manually operated valves shall be equipped with lever- type handles.

5.8.2 Gear operators shall be ftted with handwheels and shall be sized to comply with the requirements of 5.8.3.

5.8.3 Unless otherwise specifed in the purchase order, the length of the lever handle or the gear ratio, efciency, and handwheel diameter of gear operators shall be designed so that the required input force to fully open and close the valve shall not exceed 360 N (80 lb) when operating the valve at the manufacturer’s maximum published torque as described in 5.5.4.

5.8.4 Valves shall be closed by rotating the closure device (lever or handwheel) in a clockwise direction.

5.8.5 Position stops shall be provided for both fully open and fully closed positions of the valve.

5.8.6 Handwheels on manual gear operators shall be marked to indicate the direction of opening and/or closing.

5.8.7 Lever-type handles shall be parallel to the ball bore so that the lever always indicates the ball bore position. If the purchase order specifes round or oval direct-mounted handwheels, a permanent means of indicating the ball bore position shall be included in the handwheel design.

5.8.8 An indication parallel with the position of ball bore of the valve shall be integral with the valve stem. This indication may be by permanent marking to the top of the stem, keyways, or by the shape of the exposed stem portion. API Std 608 pdf download.API Std 608:2020 pdf free download