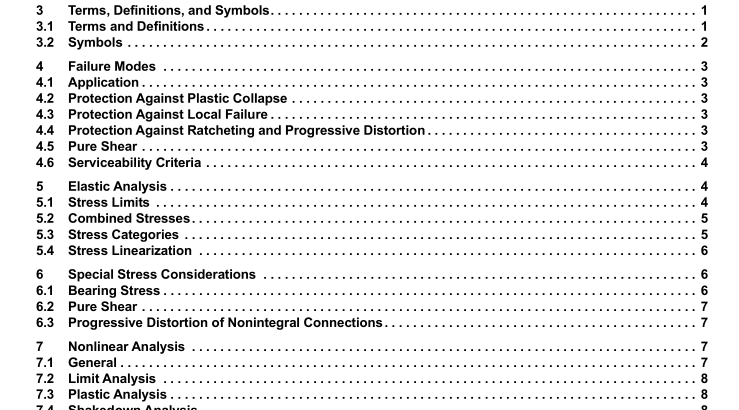

API STD 6X:2019 pdf free download.Design Calculations for Pressure-containing Equipment

4 Failure Modes

4.1 Application

NOTE A design analysis methodology and requirements are provided in this document for protection against the failure modes listed below.

The methodology assumes ductile metallic material behavior and has no provision for material defects. Other failure modes, such as bearing stress, buckling, brittle fracture, and fatigue may be applicable, but are outside the scope of this document.

Products shall be evaluated for each applicable failure mode. If multiple assessment procedures are provided for a failure mode, use of only one of these procedures shall be required to qualify the design of a product. The impact of the effect of temperature on the mechanical properties of the material shall be determined if the rated temperature exceeds 250 °F (1 21 °C).

NOTE API 6A provides guidance for testing of materials at elevated temperature and designing with the data so obtained. API TR 6MET and the reference sources listed in API 6A also provide guidance. The effect of thermal expansion on the clearances and interferences between parts may also be considered.

4.2 Protection Against Plastic Collapse Protection against plastic collapse shall be demonstrated by elastic analysis (5.3.2.1 , 5.3.2.2, and 5.3.2.3), limit analysis (7.2), or plastic analysis (7.3).

NOTE Specific requirements for the hydrostatic test case are given for elastic analysis (5.3.2.1, item (a) and 6.2) and limit analysis (7.2).

4.3 Protection Against Local Failure Protection against local failure shall be demonstrated by elastic analysis (5.3.2.4) or plastic analysis (7.3).

4.4 Protection Against Ratcheting and Progressive Distortion Protection against ratcheting and progressive distortion shall be demonstrated by elastic analysis (5.3.2.1 , item (b); 5.3.3; and 6.3) or plastic analysis (7.4).

4.5 Pure Shear Protection against failure by pure shear shall be demonstrated by the methods in 6.2.

4.6 Serviceability Criteria Serviceability criteria that ensure the performance and functionality of the product, as defined by the manufacturer, shall be satisfied at critical locations when subjected to the operating and hydrostatic test conditions.

NOTE Examples of serviceability criteria are limits on deflections or rotations that may cause leakage or operational concerns.

5 Elastic Analysis

5.1 Stress Limits

5.1.1 General For elastic analysis, stress components shall be calculated, combined, and then compared to limits for each category of stress based on multiples of the design stress intensity, S m , for the material in use and for the category of stress. For API 6A equipment, standard and non-standard materials shall be as defined in API 6A and the corresponding design stress intensity per 5.1 .2 or 5.1 .3 shall be used. For other equipment, the design stress intensity per 5.1 .2 shall be used, unless otherwise required by the product specification or manufacturer’s specification.

5.1.2 Standard Materials

The design stress intensity shall be two-thirds of the minimum specified yield strength, S y .

The maximum allowable general primary membrane stress intensity at hydrostatic shell test, S t , shall be 90 % of the minimum specified yield strength.

5.1.3 Non-standard Materials

The design stress intensity shall be the minimum of two-thirds of the minimum specified yield strength, S y , or one-half of the minimum specified ultimate tensile strength, R m .

The maximum allowable general primary membrane stress intensity at hydrostatic shell test, S t , shall be the minimum of 90 % of the minimum specified yield strength or two-thirds of the minimum specified ultimate tensile strength, R m .

5.4 Stress Linearization When it is necessary to extract the membrane and bending stresses from FEAs, a numerical technique called “linearization” shall be used.

NOTE This procedure involves numerical integration of the stress components to separate the membrane and bending portion of the stress from the total stress. The total stress includes the nonlinear peak stress. Guidance on linearization can be found in the 201 3 ASME Boiler and Pressure Vessel Code, Section VIII, Division 2, Annex 5.A.

6 Special Stress Considerations

6.1 Bearing Stress The manufacturer shall specify limits on the average bearing stress or other methods for assessing bearing stress. API STD 6X pdf download.API STD 6X:2019 pdf free download