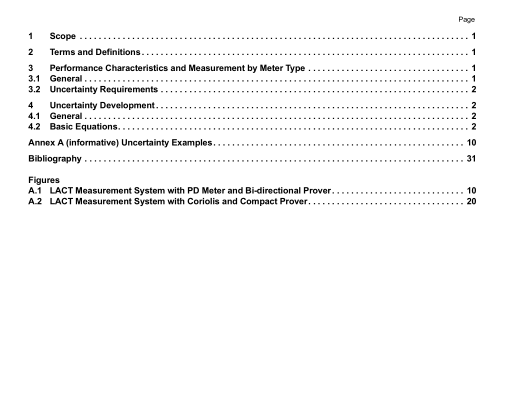

API TR 2579:2020 pdf free download.Liquid Hydrocarbon Measurement Uncertainty Calculations

This document provides guidelines for the calculation of uncertainty for field stored and transported hydrocarbon liquids. Special emphasis is placed on the measurement uncertainty of crude oils measured at tanks, by lease automatic custody transfer (LACT), and alternative measurement systems.

2 Terms and Definitions For the purposes of this document, the following definitions apply.

2.1 accuracy The closeness of agreement between a measured quantity value and a true quantity value of a measurand.

2.12 metering or measurement system A combination of primary, secondary, and/or tertiary measurement components necessary to determine the flow rate.

2.1.3 calibration A set of operations that establish, under specified conditions, the relationship between the values indicated by a measuring device and the corresponding known values indicated when using a suitable measuring standard.

2.14 performance The response of a measurement device to influence parameters such as operating conditions, installation effects, and fluid properties.

2.16 uncertainty The range or interval within which the true value is expected to lie with a stated degree of confidence. Describes the range of deviation between a measured value and the true value, expressed as a percentage. For example, a device with an accuracy of 2 % would have an uncertainty of ±2 %.

3 Performance Characteristics and Measurement by Meter Type

3.1 General

The primary purpose of a liquid hydrocarbon meter for any application is to measure the flow. The uncertainty of measurement depends on the measurement equipment selected for the application, proper installation of the equipment, the ability to inspect, verify, or calibrate the various measurement system components, and the frequency of those maintenance activities. The performance of the meter may also depend on the piping configuration and compensation for variability of operating pressure, temperature, and fluid composition. It is important to recognize individual influence parameters and their effect on the measurement. Since the principle of operation and differing influence parameters have varying degrees of influence by meter type, it is important to identify and define the significant influence factors for the meter to determine the total or combined measurement uncertainty.

3.2 Uncertainty Requirements General

The purpose of this document is to develop the uncertainty representations and example calculations for meters, provers, and associated equipment used on any metering system such as LACT systems, which can be used to address uncertainty requirements. Focus is placed on Coriolis and positive displacement meters since they are the most commonly used on LACT systems to measure crude oil quantities. With the proper understanding of individual system component uncertainties, the overall system uncertainty can be calculated for metering systems in the design phase or already in operation in the field.

3.2.2 Specifics of Requirements

The sources of uncertainty that are addressed arise from the fllowing.

Meter measurement:

一linearity;

一themmal and pressure vaniation;

一deviation from meter factor proving conditions.

一Fluid properties:

一themal, pressure, and viscosity variation;

一profile deviation impact

一Prover,

一temperature, pressure variation.

一Associated devices:

一sediment and water, density.

一Calibration:

一temperature, pressure, density, viscosity, sediment and water.

4 Uncertainty Development

4.1General

4.1 General The work by Dahl et al. (2003) [9] was used as basis for the development of this document. Refer to Annex A for examples of the uncertainty calculation procedure.

4.2 Basic Equations General NOTE The basic equations developed in the handbook by Dahl et al. (2003) [9] follow the development from ISO 5168:1978 [7] and ISO/IEC Guide 98-3 [8] .

where

the term on the left-hand side is the square of the overall uncertainty in the metering system in percent;

the right-hand side consists of the squares of uncertainty contributions from (in order): oil and steel expansion, calibration, prover, meter, sediment and water determination, and flow;

Do is intended to signify the measurement by the primary flow meter after corrections from the proving and calibrations have been applied.

Note that this development assumes that the different uncertainties are uncorrelated, an approach that may be conservative. Each term of this development is discussed in the following sections.API TR 2579 pdf download.API TR 2579:2020 pdf free download