API TR 1179:2019 pdf free download.Hydrostatic Testing as an Integrity Management Tool

4.3 Integrity Assessment Hydrostatic tests may be used as a means of confrming reliability of a previously in-service pipeline. A properly designed hydrostatic test can verify that pipeline threats have been adequately managed. Depending upon the threats assessed through the hydrostatic test program, these reliability tests may serve as a one-time assessment of threats or, alternatively, they may be part of a series of iterative integrity assessment steps.

ASME B31.8S and API 1160 provide guidance on applicability of hydrostatic testing for integrity assessment. These references state that hydrostatic testing can be used as an assessment for time-dependent threats 7 and threats that have the potential for enlargement by pressure cycle-induced fatigue. Time-dependent threats require periodic reassessment to ensure effective threat management. When used to assess time-dependent threats, each test should be designed to specifcally target the relevant threat(s), with an objective to establish a reassessment interval with a desired safety factor. Gas pipeline operators are currently more likely than liquid operators to use hydrostatic testing to manage the threat of SCC due to diffculty with use of ultrasonic crack-de- tection tools in dry gas pipelines.

Hydrostatic testing can additionally be used as a one-time event to assess resident material threats such as manufacturing faws not susceptible to time-dependent faw degradation mechanisms, including evaluation of the pipe against the threat of defective longitudinal seam welds. For example, an operator may use a test to verify that ERW or other seam workmanship (e.g. legacy 8 manufacturing methods such as a lap-welded or hammer-welded seam) is not causing an unacceptably low factor of safety. Limited beneft is realized through hydrostatic testing for the assessment of circumferentially oriented defects, such as defective girth welds, as there is relatively little resulting stress in the pipe’s axial direction and the primary stress is oriented in the hoop direction.

Hydrostatic testing can be used to establish confdence in an integrity management program, or in a process within an integrity management program.

For instance, a test may be used to validate an ILI process. This valida- tion objective could extend beyond that of ILI data analysis processes to include vendor selection, qualifcation, inspection, excavation, feld nondestructive examination (NDE), and repair methods.

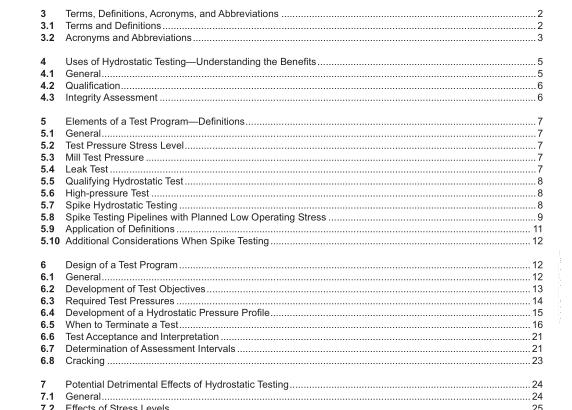

5? Elements of a Test Program—Defnitions

5.1 General There is broad interpretation within the pipeline industry regarding requirements and defnitions for various aspects of pressure test programs. The focus of this section is to provide consistent parameters for consideration to aid in classifcation of a hydrostatic test, and the defnitions below are presented to provide consistent terminology for application in consideration of pressure testing. It should be noted that “integrity test,” a widely-used generic testing term, has not been specifcally applied within this report; it is considered that each of the tests described below are a form of integrity test.

This section of the document does not include provisions for determining when and how to apply a hydrostatic test, recommendations on which testing type is most appropriate, or defning the test’s objectives. Target hydro- static pressures are driven by the hydrostatic test’s goals, the pipeline’s characteristics, the integrity threats being evaluated, consideration of all associated risk factors, and the supporting engineering analyses. A theoretical application of testing defnitions is provided in Section 5.9 of this document.

5.2 Test Pressure Stress Level When discussing hydrostatic test stress levels, it is common in the pipeline industry to refer to the test pipe that will be exposed to the highest ratio of the stress levels during the test and SMYS (e.g. a test to 90 % SMYS). The location of this limiting pipe is not necessarily associated with the location of maximum test pressure. It is noted that stress level is a measurable component of the pipe material; this useful shorthand is important to understand for anyone designing a hydrostatic test.API TR 1179 pdf download.API TR 1179:2019 pdf free download