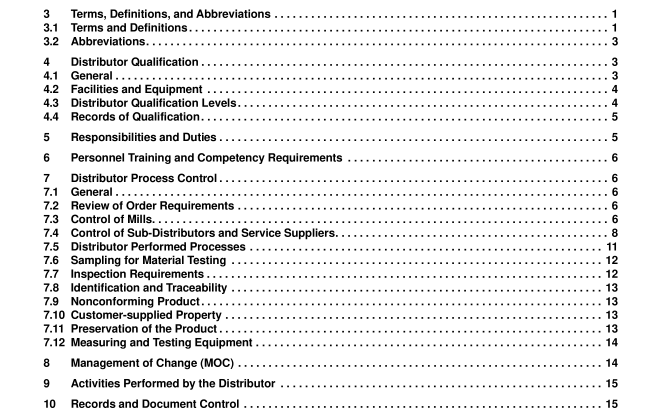

API STD 20J:2017 pdf free download.Qualification of Distributors of Metallic Materials for Use in the Petroleum and Natural Gas Industries

b) Verification of a Quality Management System through third-party certification or audit and

c) Verification of product from initial order to ensure conformance to the agreed-upon purchase requirements, as specified in 7.3.4 of this document.

7.3.2.2 In addition to DQL-1 requirements, a DQL-2 distributor shall also:

a) Maintain a documented procedure to validate the mill initial order to the agreed-upon purchasing requirements.

The documented procedure shall include requirements and acceptance criteria for the following:

1) chemical analysis;

2) mechanical testing;

3) NDE;

4) Microstructure.

b) Perform an assessment of the mill’s capabilities and controls through either:

1) Verification of an active API license for applicable products or

2) an on-site technical audit or

3) A technical questionnaire that shall be reviewed by competent personnel. If the response does not meet the distributor’s requirements, an on-site technical audit shall be performed. The technical questionnaire shall include, as applicable to the scope of supply, the following:

i) scope of capabilities (grades, sizes, product form);

ii) melt practice, pouring/casting, and capacity (tonnage);

iii) testing capability and equipment;

iv) calibration of measuring and testing equipment;

v) outsourced activities;

vi) processing, such as rolling, forging, straightening, etc.;

vii) heat-treatment capabilities to include heat-treatment furnace qualification, method used for instrument calibration, and quench control;

viii) NDE capabilities;

ix) certifications/records;

x) industry licenses or accreditation;

xi) process monitoring and controls.

NOTE An example of an extensive questionnaire (Mill Technical Assessment) is included in Annex A for use as a uide for

a distributor in preparing a technical questionnaire.

7.3.2.3 Records of the results of the mill approval, including resulting actions, shall be maintained.7.3.3 Periodic Evaluation of a Mill

7.3.3.1DQL-1 Requirements

The distributor shall maintain a documented procedure for the monitoring and re-evaluation of mills. The procedureshall identify the minimum performance requirements and the process for continual monitoring of the mill againstthese requirements. The frequency of periodic evaluation shall be based on a risk assessment of product quality andthe availability of alternate sources. The risk assessment shall take into account a mills performance history,purchasing frequency, and any changes that have occurred at the facility. The planned frequency of the evaluationshall be documented.

The mill re-evaluation shall be performed through one or more of the following:-on-site audit;

technical assessment;

review of supplier performance; or

verification of an active applicable APl license.

The procedure shall address the actions required when a mill does not meet these requirements.Records of the results of the mill periodic evaluation, including resulting actions, shall be maintained.

7.3.3.2Additional Requirements for a DQL-2 Distributor

A DQL-2 distributor shall identify material for periodic evaluation that shall be tested in accordance with theapplicable material standard by a laboratory approved for the required testing service, as specified in 7.4.3. Thefrequency of the evaluation shall not exceed 36 months and shall be documented.

Records of the results of the periodic evaluations, including resulting actions, shall be maintained.

7.3.4Review of Order Requirements with a Mill

7.3.4.1General

The distributor shall perform an order review with the mill to ensure that the product ordered meets the requirementsof this standard and any additional purchase order-specific requirements.

7.3.4.2 Additional Requirements for a DQL-2 Distributor

DQL-2 distributors shall maintain records of the results of the review, including any resulting actions.

DQL-2 distributors shall maintain records of the results of the review, including any resulting actions.

7.4Control of Sub-Distributors and Service Suppliers

7.4.1 General

Distributors shall maintain a documented procedure to ensure that outsourced activities conform to specifiedrequirements.The procedure shall conform to the purchasing requirements in API Specification Q1.

7.4.2lnitial Approval of Sub-Distributors

7.4.2.1Distributors may procure materials from sub-distributors. The distributor shall ensure that the subdistributor is qualified through one of the below methods:

7.4.2.2 A DQL-1 distributor shall ensure the sub-distributor maintains a QMS or meets one of the following:

a) verification that the sub-distributor’s QMS conforms to the quality system requirements specified for suppliers by the distributor; or

b) assessment of the sub-distributor to meet the distributor’s purchasing requirements; orc) assessment of the product upon delivery or activity upon completion.API STD 20J pdf download.API STD 20J:2017 pdf free download