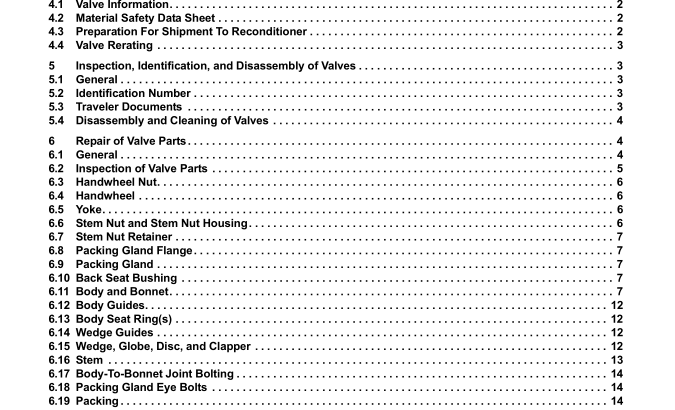

API RP 621:2017 pdf free download.Reconditioning of Metallic Gate, Globe, and Check Valves

6.3 Handwheel Nut

6.3.1 Handwheel nut shall be visually inspected for wear or excessive corrosion of the threads or contact area.

6.3.2 If the handwheel nut is defective, it shall be repaired or replaced.

6.3.3 If the handwheel nut is locked into place with a setscrew or some other device, the locking mechanism shall be in place and fully functional.

6.4 Handwheel

6.4.1 Handwheel shall be visually inspected for worn, bent, or broken spokes and rim.

6.4.2 Handwheel shall be inspected to verify proper engagement to the stem yoke nut. If the valve does not have a yoke nut, the handwheel shall be inspected to verify proper engagement to the stem.

6.4.3 A defective handwheel shall be repaired by the appropriate repair method for the defect: Bent spokes, hub, or rim may be straightened by pressing. Broken spokes or rim (if made of a weldable grade material) may be weld repaired.

6.4.4 If the defect(s) cannot be repaired, the handwheel shall be scrapped and replaced with one of similar size and material.

6.4.5 All parts of the handwheel and any repairs shall be free of burrs, metal splinters, and sharp metal edges.

6.5 Yoke

6.5.1 Yoke shall be visually inspected for defects and for proper alignment of the stem through the stem nut, packing chamber, back seat bushing, and wedge connection.

6.5.2 Defects shall be repaired by generally accepted repair procedures, such as welding or machining.

6.6 Stem Nut and Stem Nut Housing

6.6.1 Stem nut and stem nut housing shall be visually inspected for corrosion, galling, or wear of bearing surfaces.

6.6.2 Defects shall be repaired by welding (if of a weldable material), machining or other appropriate methods. If the defects cannot be repaired, the nut/housing shall be replaced.

6.6.3 If a thrust bearing was used by the OEM in the design of the valve, the thrust bearing must be in place and free of excessive corrosion or wear. If necessary for smooth operation of the stem nut, the thrust bearing shall be replaced.

6.6.4 Internal threads of a tapped hole in the stem nut housing shall be visually inspected and defective threads shall be repaired and/or re-tapped.

6.6.5 Lubrication fittings shall be replaced.

6.6.6 If applicable, external threads on the stem nut shall be visually inspected for proper engagement to the handwheel nut.

6.6.7 Internal ACME threads of the stem nut shall be visually inspected for condition and proper engagement with the external threads of the stem in accordance with ASME B1.5 or B1.8.

6.7 Stem Nut Retainer

6.7.1 If applicable, stem nut retainer shall be visually inspected for excessive corrosion and wear. Threads shall be inspected for general condition and proper engagement to the valve bonnet or yoke.

6.7.2 Defective stem nut retainer shall be repaired by welding and/or machining. If defects cannot be repaired, stem nut retainer shall be replaced.

6.7.3 After assembly and before shipping, the stem nut retainer shall be tack welded, or otherwise locked, to the yoke.

6.8 Packing Gland Flange

6.8.1 Packing gland flange shall be visually inspected for excessive corrosion, cracks, and straightness.

6.8.2 Defective flange shall be repaired or replaced.

6.9 Packing Gland

6.9.1 Packing gland shall be visually inspected for excessive corrosion or wear and checked dimensionally for proper fit to the stuffing box and to the stem in accordance with OEM dimensions and tolerances. When OEM dimensions and tolerances are not available, the clearances specified in Figure A.1 may be used, when approved by the Owner.

6.9.2 A damaged or broken packing gland shall be repaired or replaced.

6.10 Back Seat Bushing

6.10.1 A back seat bushing’s ability to seal against the opposing angle of the stem shall be assessed by visually inspecting for corrosion, wear, and cracks. Sealing surface shall have a finish Ra of 32 µin. (0.8 µm) or smoother.

6.10.2 A defective bushing shall be repaired with an owner approved repair procedure or the bushing shall be replaced.API RP 621 pdf download.API RP 621:2017 pdf free download