API Spec 15PX:2018 pdf free download.Specification for Crosslinked Polyethylene (PEX) Line Pipe

D4364.Exposed pipe shall also have an elongation at break according to ASTM D638 or IlSO 527-1 of notless than 50 % of the elongation at break of unexposed pipe.

5.3.6Color

lf the color of the pipe is black, the formulation shall contain carbon black, meeting the requirements of5.3.5 as a colorant.

5.4 Finish and Workmanship

5.4.1 Pipe Ends

Pipe ends shall be plain and squared, or with flared ends, for use with flange connections.Cut pipe endsshall be clean without ledges,shaving tails, burrs, or cracks.

Other pipe end conditions shall be agreed between the purchaser and the seller.

5.4.2Finish

The interior and exterior of the pipe shall be uniform in finish, without voids, cracks, crazing, foreigninclusions, or deep scratches.

5.4.3 Workmanship

The pipe shall be homogeneous throughout and free of visible cracks, holes, foreign inclusions, or otherdefects. The pipe shall be as uniform as commercially practicable in color, opacity, density, and otherphysical properties.

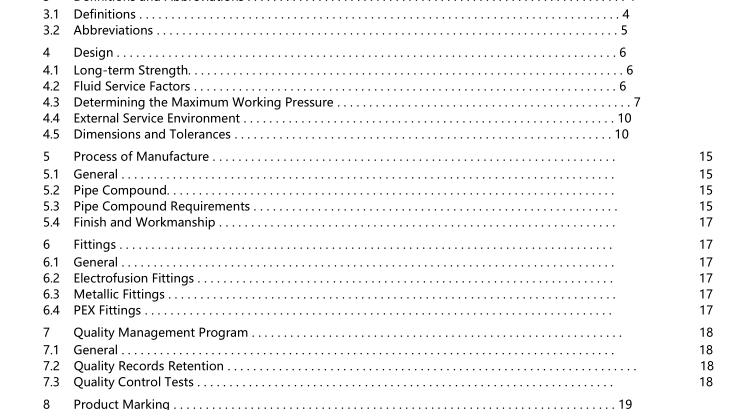

6Fittings6.1General

All fttings, plastic or metallic, shall be demonstrated by the pipe manufacturer to meet or exceed the thermaland mechanical properties of the pipe.

6.2Electrofusion Fittings

Electrofusion fttings furnished for use with this specification shall meet the requirements of ASTM F1055or ISO 14531-2.Electrofusion fttings shall not be used in services with HeS content of 100 ppm or higher.

NOTE lf the specified electrofusion fittings are HDPE or PEX fittings and do not have the same high-temperaturecapabilities of the PEX pipe with which they will be used, the designer is cautioned that the system design pressureand temperature are limited by the lowest rated component.

6.3Metallic Fittings

Mechanical metallic fittings furnished for use with this specification shall meet the requirements ofISO14531-3 and the requirements of sections 4.2.4.3,4.2.4.3.1, and 4.2.4.3.2 of API 15S,2nd Edition.6.4 PEX Fittings

Reducers are component fittings that allow two pipes of different diameters to be connected.Thermoformedreducers and elbows made of PEX pipes may be used.

Molded or fabricated PEX fittings may be used.PEX fittings shall be manufactured according to applicableASTM or ISO standards, or in compliance with the manufacturer’s documented procedures approved bythe customer, whichever is more restrictive.The PEX compound used for the fittings shall comply with allthe compound requirements of this standard.When conflicts arise between standards or procedures, thisdocument’s requirements shall be followed.

The design and pressure rating of the fitting is beyond the scope of this standard and shall be establishedby the fitting manufacturer.Fittings shall meet or exceed the pressure design and requirements of thesystem.

7 Quality Management Program7.1General

Products meeting this specification shall be manufactured in a facility that maintains a written qualitymanagement system in accordance with API Q1, ISO Ts 29001, or lSO 9001.

7.2Quality Records Retention

Quality records shall remain legible, readily identifiable, and retrievable for a period of not less than10 years.

7.3Quality Control Tests

7.3.1 Dimensional Analysis

Samples for quality control testing shall be conditioned in accordance with ASTM D2122 or ISO 3126.

7.3.2 Physical Properties

a) Pipe: Refer to Table 8 for physical testing requirements for PEX pipe.

b)Fitings:Fittings intended for use with PEX pipe shall meet the dimensional, design, and performance

requirements of the applicable fitting product standard, and shall have dimensions that are compatiblewith the pipe manufactured to this standard.

c) Retesting: lf the results of any test(s) do not meet the requirements of this specification, the test(s) maybe conducted again in accordance with an agreement between the purchaser and the seller.API Spec 15PX pdf download.API Spec 15PX:2018 pdf free download