API RP 13L:2017 pdf free download.Training and Qualification of Drilling Fluid Technologists

This standard is written in two parts. The first part is a summary of basic training and knowledge that an employee or contractor shall possess in order to be identified as a rig site drilling fluids technologist or rig site drilling fluids engineer. The first part covers basic skills as would be taught in an entry-level fluids school program. The second part covers a set of advanced skills that will be required in order to support complex wells at the rig site. Levels of understanding for both core and advanced skills have been generally outlined but not totally defined.

Normative References

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

API Specification 13A, Specification for Drilling Fluid Materials

API Recommended Practice 13B-1, Recommended Practice for Field Testing of Water-based Drilling Fluids

API Recommended Practice 13B-2, Recommended Practice for Field Testing of Oil-based Drilling Fluids Terms, 3.Definitions, and Abbreviations

3.1Terms and Definitions

3.1.1

breadth

The basic knowledge common to all areas of drilling fluids technology needed by all drilling fluids technologists to demonstrate minimum competency.

3.1.2

drilling fluids engineer

A drilling fluids technologist with an engineering, geoscience, or other appropriate science discipline degree from an accredited university.

3.1.3

drilling fluids technologist

An individual with specialized knowledge of the application of drilling fluids during the drilling operation.

3.1.4

drilling fluids technician

An individual skilled in the art of testing drilling fluids in the field or the laboratory.

Abbreviated Terms

API American Petroleum Institute

BOP blowout preventer

CEC cation exchange capacity

ECD equivalent circulating density

EOWR end of well report

ESD equivalent static density

HGS high gravity solids

HSE health, safety, and environment

HTHP high temperature, high pressure

LCM lost circulation material

LGS low gravity solids

MBT methylene blue test

M f methyl orange alkalinity of the filtrate

NAF non-aqueous fluid

NPT non-productive time

OWR oil/water ratio

P m phenolphthalein alkalinity of the mud (drilling fluid)

P f phenolphthalein alkalinity of the filtrate

PPE personal protective equipment

PPT particle plugging test

PV plastic viscosity expressed in centipoise (millipascal – second) (1 cP = 1 mPa • s)

SDS safety data sheet

YP yield point expressed in pascal (pound-force per one hundred square foot)

WBM water-based mud

4.Principle

This document is a recommended practice and seeks to provide guidance for the specific knowledge

base, professional skills, and application skills needed to ensure the competency and professionalism of

individuals working in the drilling fluids industry. Drilling fluids technicians, technologists, and engineers

should use this document as an outline to self-determine any gaps in learning and seek to improve their

skills. A company contracting the service of a drilling fluids technician, technologist, or engineer should use this recommended practice as a checklist of knowledge that a technologist should be able to demonstrate proficiency in applying. Procedure

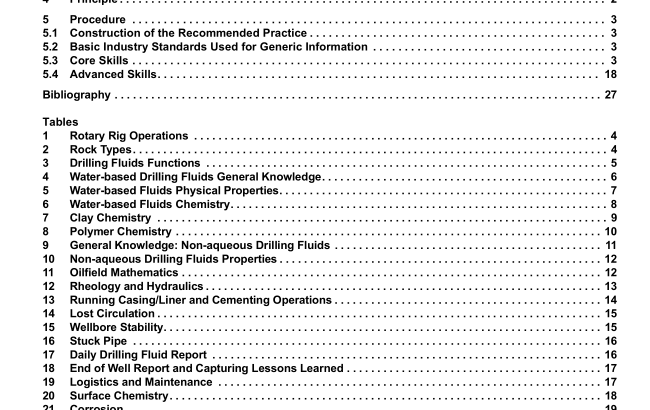

5 Construction of the Recommended Practice

5.1 This document was developed from a review of the curriculums that are followed by drilling fluids service companies in their basic schools. The output from this, Core Skills, is found in 5.3. Five key areas are identified and further broken down into topics with the breadth of knowledge expected for that topic. Subsection 5.4 is structured in the same way and identifies additional skills required to work on complex wells. Skills identified in 5.4 are not taught as part of basic training, rather these are additive skills attained throughout a career as a rig site drilling fluids technologist or rig site drilling fluids engineer.API RP 13L pdf download.API RP 13L:2017 pdf free download