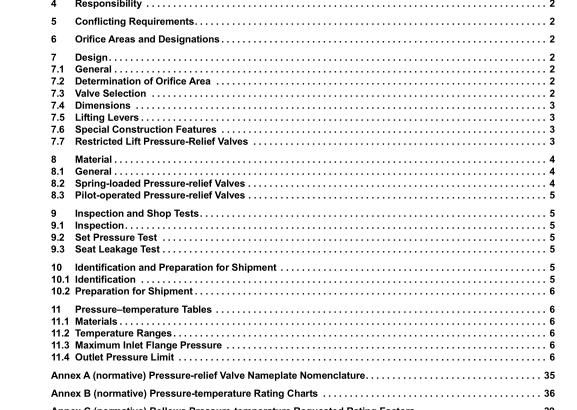

API 526 7th:2017 pdf free download.Flanged Steel Pressure-relief Valves

10.2 Preparation for Shipment

Each pressure-relief valve shall be prepared for shipment as follows.

a) After test and inspection, all exterior surfaces, except flange facings, shall be painted as agreed upon by the manufacturer and the purchaser. Corrosion-resistant materials need not be painted. Flange facings shall be coated with a suitable corrosion inhibitor.

b) Threaded openings shall be plugged with suitable protective devices. Temporary plugs should be readily distinguishable from permanent metal plugs.

c) Inlet and outlet flanges shall be protected to prevent damage from or entrance of foreign material during shipment. 11 Pressure–temperature Tables Table 3 through Table 30 provide flange and bellows pressure limits, materials and dimensions for pressure-relief valves. Table 3 through Table 16 are specific to spring-loaded pressure-relief valves, while Table 17 through Table 30 are specific to pilot-operated pressure-relief valves.

11.1 Materials Materials for the body/bonnet and springs are indicated for spring-loaded pressure-relief valves. The material for the body is indicated for pilot-operated pressure-relief valves. For further description of body and bonnet materials see 8.2 for spring-loaded pressure-relief valves and 8.3 for pilot-operated pressure-relief valves. Other combinations of pressure, temperature, size and materials are outside the scope of this standard.

11.2 Temperature Ranges Temperature ranges are provided to indicate distinct changes in body and/or spring material requirements.

11.3 Maximum Inlet Flange Pressure The maximum inlet flange pressure is provided at specific temperatures. This represents the maximum set pressure for the temperature. The maximum inlet flange pressure values are per ASME B16.34 unless enclosed in parentheses. Values enclosed in parentheses are limited by this standard to a value less than the ASME B16.34 value. Inlet flange pressure values at other temperatures may be interpolated using the charts from Annex B or from tables in ASME B16.34, if these values do not exceed the limits in parentheses. The charts in Annex B are produced from ASME B16.34 with permission. Pressure changes within the temperature ranges above may not be linear.

11.4 Outlet Pressure Limit

11.4.1 Outlet Flange Limit Outlet flange pressure limits are shown in the “Flange Rating” column and correspond to the ASME B16.34 value unless enclosed in parentheses. If the value is shown in parentheses, the value is less than that provided in ASME B16.34. The values in the “Flange Rating” column at 100 °F are the limit for this standard. Outlet flange pressure values at other temperatures may be interpolated using charts from Annex B or from tables in ASME B16.34, if these values do not exceed the value at 100 °F above. The charts in Annex B are produced from ASME B16.34 with permission. Pressure changes within the temperature ranges above may not be linear.

11.4.2 Bellows Limit The bellows pressure limit is listed in the “Bellows Rating” column and represents the design pressure of the bellows at the outlet temperature of 100 °F. The bellows pressure values at other temperatures may be determined by multiplying the above pressure value at 100 °F by the factor from Annex C.API 526 7th pdf download.API 526 7th:2017 pdf free download