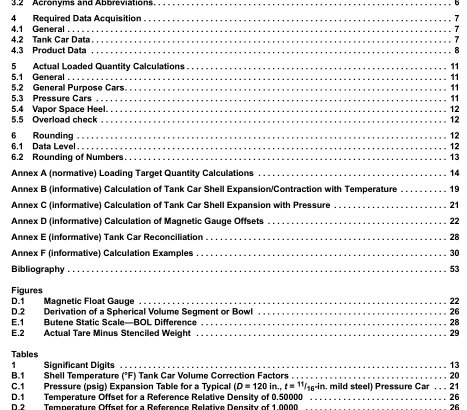

API MPMS 12.1.2:2018 pdf free download.Manual of Petroleum Standards Chapter 12—Calculation of Petroleum Quantities Section 1—Calculation of Static Petroleum Quantities Part 2—Calculation Procedures for Tank Cars

4.2.5 Tank Car Capacity

Table The tank car capacity table can be obtained from the tank car owner, manufacturer, or industry database. Care must be taken to ensure that the correct capacity table is used (it is not uncommon for individual locations to have outdated or incorrect tables). A car’s useful statutory life is 50 years, so there may be several different versions in use for the same car. Currently, there is no industry standard format and a manufacturer may have changed the format several times over the years. Therefore, it is generally impossible to determine by observation when the table was issued and whether it is more current than another table.

When in doubt, contact the owner of the tank car. The table may be based on either innage or outage gauges and may indicate either liquid or vapor space gallons.

These are referred to as Outage Liquid, Outage Vapor, Innage Liquid, or Innage Vapor tables. Care must also be taken to ensure that the capacity table is used properly. There may also be no indication as to what type of table it is, and therefore the table may be used incorrectly.

The manufacturers may have developed these tables using the inside top of the shell at the center of the car, the rail car shell-full point, as a reference point. Distance increments (normally 1 / 4 in.) are then listed from the reference point down to the liquid surface (outage) or from the bottom of the car directly below the reference point to the liquid surface (innage), and the corresponding liquid or vapor volume is calculated and inserted in the table. Using an Innage Liquid table as an Outage Vapor table (or vice versa) for a funnel flow car will introduce an error on the order of several hundred gallons as the tables are not symmetrical.

Experience has shown that table misinterpretation is the most common cause of calculation error. The same capacity table may be assigned to hundreds of dimensionally similar, but not identical, tank cars. Tank cars cannot be constructed to exactly match the table, but the table may be mathematically sized to each tank car by applying the capacity table adjustment factor (CTAF), calculated by dividing the stenciled volume (V s ) by the table max volume (V tblmax ), to every gauge volume coming out of or calculated volume going into the table.

4.2.6 Manway Nozzle Height Liquid levels are most commonly determined via outage measurements, especially if the product is hot and solidifies at ambient temperature. In practice, it is difficult if not impossible to take an outage measurement from the inside top of shell reference point unless a proper measuring device (commercially available) is at hand. Absent such a device, it is much easier to measure from the top of the open manway nozzle nearest the center point of the car. This requires measurement of the offset between the rail car reference gauge point and the shell-full point, which in most case will be the manway nozzle height.

This offset must be measured with the proper instrument (also commercially available) for maximum accuracy. If a proper device is not available, numerous “work arounds” (usually containing systematic errors) have been developed in the field to compensate.

A manway may be ground flush with the shell at the weld, however many manways penetrate the tank car’s shell by varying depths, as much as 3 in. This penetration is not part of the manway’s height and should not be included. Some tank cars may already have their original tables changed to incorporate the manway height at the request of the car’s owner. Pressure cars have a secured hatch that usually contains thermowells, magnetic float gauges, and loading valves permanently installed. The manway height is incorporated in the magnetic float gauge rod.

4.3 Product Data

4.3.1 Traceability All measurements shall be traceable to a national standard such as NIST. The verification of the field equipment shall be performed (and documented) periodically as required by the applicable API standards.

4.3.2 Actual Liquid Temperature Once the car is loaded, a temperature must be taken from the center of the product at the time of gauging (after motion ceases). For very hot products like asphalt, sulfur, etc., the temperature and gauge should be taken as soon as possible, as the product will quickly stratify, forming a nonlinear temperature gradient. API MPMS 12.1.2 pdf download.API MPMS 12.1.2:2018 pdf free download