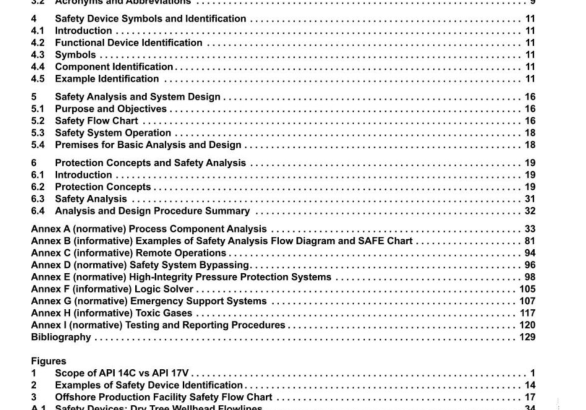

API RP 14C:2017 pdf free download.Analysis , Design , Installation , and Testing of Safety Systems for Offshore Production Facilities

Safety Device Symbols and Identification

4.1 Introduction A standard method for identifying , abbreviating , and symbolizing individual safety devices is needed to promote uniformity when describing or referring to safety systems. This method can be used to illustrate safety devices on piping and instrument diagrams (P&IDs) and other drawings and to identify an individual safety device for any purpose. Abbreviations and symbols are derived , insofar as possible , from ISA-5.1 . Additional applications that adhere to this standard may be derived as required. However , certain abbreviations have such wide oil field acceptance that their continued use is justified even though they do not strictly conform to ISA- 5.1 .

The abbreviations SSV ! f or surface safety valve , SDV for shutdown valve , and ESD for emergency shutdown are examples

4.2 Functional Device Identification Each safety device should be identified by a system of letters used to classify it functionally. The functional identification includes one first letter covering the measured or initiating variable and one or more succeeding letters covering the function of the device. The term “safety” (S) applies to safety devices and is used as the second letter of sensing and self-acting devices. If two or more devices of the same type are installed on a single component , each device should be numbered or lettered consecutively and the number or letter shown following the functional identification. If only one device is installed , the dev ice number or letter may be om itted.

4.3 Symbols The circular balloon is used to tag distinctive symbols , such as a pressure-relief valve. In such instances , the line connecting the balloon to the instrument symbol is drawn close to , but not touching , the symbo l. In other instances , the balloon serves to represent the device prope r. Table 1 and Table 2 illustrate example symbols for various safety devices.

4.4 Component Identification The comp lete identification of a safety device includes reference to the component that it protects. This is accomplished by following the device functional identification or device number , if applicable , with a component identification. Components should be identified in accordance with Table 3. The first letter is the component type and shall be one of the letters in the code column under component type. The letter “Z” is used to cover a component not listed. The second and third letters may be used to further define or otherwise modify the first characte r. The last four characters identify the specific componen t. These characters are user assigned and shall be unique to the component at the lar location.

4.5 Example Identification Example applications of the identification method are illustrated in Figure 2.

5 Safety Analysis and System Design

5.1 Purpose and Objectives

5.1 .1 The purpose of a production facility safety system is to protect personnel , the environment , and the facility from threats to safety caused by the production process. The purpose of a safety analysis is to identify undesirable events that can pose a threat to safety or the environment , and define reliable protective measures that prevent such events or minimize their effects if they occur. Potential threats to safety and/or the environment are identified through proven systems analysis techniques that have been adapted to the production process. Recommended protective measures are common industry practices proven through long experience. The systems analysis and protective measures have been combined into a safety analysis for offshore production facilities.

5.1 .2 The content of this document establishes a firm basis for designing and documenting a production facility safety system for a process composed of components and systems normally used offshore. It also establishes guidelines for analyzing components or systems that are new or significantly different from those covered in this documen t. However , it is incumbent on the user to apply appropriate additional hazardous analysis methodologies to ensure that hazards are identified and mitigated.

5.1 .3 Before a production facility safety system is placed in operation , procedures should be established to ensure continued system integrity. Annex B may be used for this purpose. 5.2 Safety Flow Chart 5.2.1 Figure 3 is a safety flow chart depicting the manner in which undesirable events could result in personnel injury , environmental impact , or facility damage. It also shows where safety devices or procedures should be used to prevent the propagation of undesirable events. As shown on the chart , the release of hydrocarbons is a factor in virtually all threats to safety. Thus , the major objective of the safety system should be to prevent the release of hydrocarbons from the process and to minimize the adverse effects of such releases if they occur.API RP 14C pdf download.API RP 14C:2017 pdf free download