API Spec 12P:2016 pdf free download.Specification for Fiberglass Reinforced Plastic Tanks

Modulus of elasticity and ultimate stress shall be determined in accordance with ASTM D638. The specified test shall be conducted for each standard composite combination used by the manufacturer. Test specimens shall be constructed with resins containing all additives used in the finished product. If S a calculated by Equation (2) is greater than 0.1 0 of the ultimate tensile stress, then S a becomes S a = 0.1 0 S u . Minimum shell thickness shall be determined using Equation (1 ), but shall not be less than 4.8 mm (0.1 875 in).

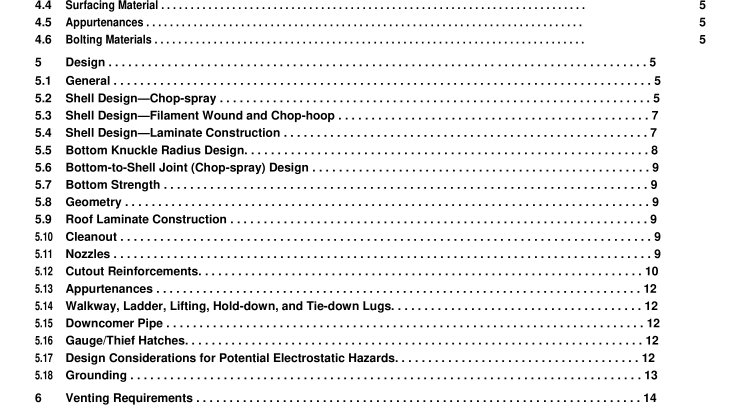

5.4 Shell Design—Laminate Construction

5.4.1 General The laminate comprising the structural components (bottom, cylindrical shell, and roof) shall consist of an inner surface, interior layer, structured layer, and an exterior layer.

5.4.2 Inner Surface The inner surface shall be between 0.254 mm to 0.508 mm (0.01 0 in. to 0.020 in.) of reinforced resin-rich material, reinforced with a chemical-resistant glass fiber surface veil or with an organic fiber surface veil, as specified in the Data Sheet. The manufacturer shall provide documentation that the material utilized for the inner surface layer is suitable for the fluid specified in the Data Sheet. This resin-rich surface shall contain less than 20 % by weight of reinforcing material.

5.4.3 Interior Layer To eliminate weeping, the inner surface exposed to the corrosive environment shall be applied over a an interior layer composed of resin, reinforced only with non-continuous glass-fiber strands applied in a minimum of two piles of chopped-strand mat equivalent to a total of 0.92 kg/m 2 (3 oz/ft 2 ). As an alternative, a minimum of two passes of chopped roving with a minimum length of 1 2.7 mm (0.5 in.) to a maximum length of 50.8 mm (2 in.) shall be applied uniformly to an equivalent weight of 0.92 kg/m 2 (3 oz/ft 2 ). Each ply of mat or pass of chopped roving shall be rolled prior to the application of additional reinforcement. The combined thickness of the inner surface and interior layer shall not be less than 2.03 mm (0.080 in.). To prevent weeping, glass content of the inner surface and the interior layer combined shall be 27 ±5 % by weight when tested in accordance with ASTM D2584.

5.4.4 Structural Layer (Chop-hoop, Filament Wound) Subsequent reinforcement shall be continuous strand roving. The thickness of the structural layer shall be sufficient to provide minimum strength requirements at various tank heights, as specified in Section 5.3. If additional reinforcement is required, woven fabric, unidirectional fabric, chopped-strand mat, or chopped strands interspersed in the winding may be used to provide additional strength. Glass content of this structural layer shall range from 45 % to 55 % for chop-hoop wound laminates and from 50 % to 80 % for filament wound laminates when tested in accordance with ASTM D2584.

5.4.5 Structural Layer (Chop-spray) As an alternative to 5.4.4, subsequent reinforcement shall consist of 0.46 kg/m 2 (1 .5 oz/ft 2 ) chopped strand mat or an equivalent weight of chopped roving and an additional number of alternating piles of 0.81 kg/m 2 (2.7 oz/ft 2 ) woven roving and 0.46 kg/m 2 (1 .5 oz/ft 2 ) chopped-strand mat, or equivalent chopped roving, as required to achieve the thickness calculated per 4.2. Each successive ply or pass of reinforcement shall be rolled prior to the application of additional reinforcement. Glass content of this structural layer shall be a minimum of 35 % when tested in accordance with ASTM D2584. Alternating layers of directional reinforcement shall be lapped a minimum of 38.1 mm (1 .5 in.) with laps staggered at least 57.1 5 mm (2.25 in.) from one layer to the next.

5.4.6 Exterior Layer Tank shell, bottom, and roof shall have an exterior layer consisting of chopped strand, chopped-strand mat, or surfacing mat. No glass fibers shall be exposed. Resin used in the exterior layer shall be resistant to ultraviolet degradation. Ultraviolet resistance shall be accomplished as specified by 4.2.2.

5.5 Bottom Knuckle Radius Design The bottom knuckle shall be reinforced with an overlay of glass fiber and resin extending from the flat bottom tangent line upward a minimum of 304.8 mm (1 2 in.), with an additional 1 01 .6 mm (4 in.) of thickness transition. Reinforcement of the knuckle radius shall taper so that it is tangent with the flat bottom and shall not extend beyond the tangent line onto the tank bottom. The reinforced perimeter shall not prevent the bottom from uniformly contacting a flat support surface when liquid covers the bottom inside of the tank. The minimum thickness of this radius section shall be equal to the combined thicknesses of the bottom shell wall and the bottom. The minimum acceptable knuckle radius shall be 2 in. (50.8 mm), as shown in Figure 1 .API Spec 12P pdf download.API Spec 12P:2016 pdf free download