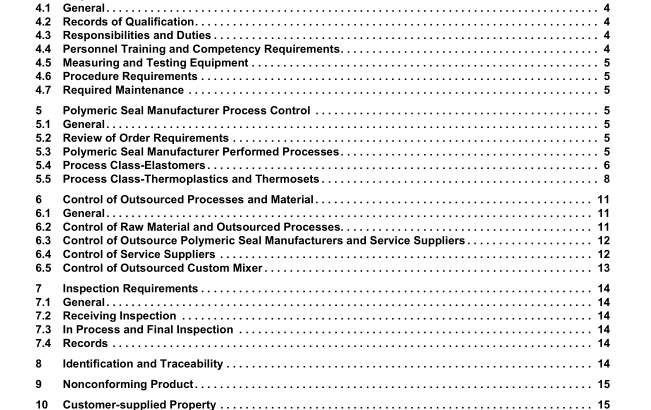

API St 20L:2018 pdf free download.Qualification of Polymeric Seal Manufacturers for Use in the Petroleum and Natural Gas Industries

4.5 Measuring and Testing Equipment The polymeric seal manufacturer shall maintain a procedure in order to ensure that testing, measurement, and monitoring equipment is calibrated and maintained, and that the equipment is used in a manner that is consistent with monitoring and measurement requirements. Calibration shall conform to and be traceable to nationally or internationally recognized standards, as applicable. Records of calibration shall be maintained.

4.6 Procedure Requirements All procedures referenced in this standard shall be documented, fully implemented, and maintained to ensure continued control of processes.

4.7 Required Maintenance The polymeric seal manufacturer shall have a documented preventative maintenance schedule that includes a list of the basic maintenance tasks to be performed for production equipment (mills, presses, CNC lathes, etc.).

The equipment will be operated throughout its full range of motions and operational conditions and any identified deficiencies reported and assessed for impact on equipment performance. For each piece of equipment, records shall be kept documenting the date of inspection, when maintenance work was performed, what the work entailed, when the next maintenance is due, and any deficiencies noted and dispositioned. 5 Polymeric Seal Manufacturer Process Control

5.1 General This section addresses the required controls for a polymeric seal manufacturer to supply polymeric seals to their customer.

5.2 Review of Order Requirements

5.2.1 An order review shall be conducted prior to the polymeric seal manufacturer’s commitment to deliver a product. The polymeric seal manufacturer shall have a documented procedure for the review of order requirements that addresses, at a minimum, that:

— purchase order requirements are identified, reviewed, and understood;

— the polymeric seal manufacturer has the capability to meet the purchase order requirements;

— purchase order requirements are acknowledged and documented; — any deviations and/or clarifications accepted by the purchaser shall be documented.

5.2.2 Where contract requirements are changed, the polymeric seal manufacturer shall ensure that relevant documents are amended and that relevant personnel are made aware of the changed requirements

. 5.2.3 Records of the results of the review, including resulting actions, shall be maintained for a period of 1 0 years.

5.3 Polymeric Seal Manufacturer Performed Processes The polymeric seal manufacturer may perform additional processes on the seal. If the processes listed in Table 1 are performed, the polymeric seal manufacturer shall be in conformance with the listed standards or equivalents.

5.4 Process Class—Elastomers

General 5.4.1

In order to conform to this standard, the elastomer seal manufacturer or an external source shall have the following manufacturing equipment, as necessary, at a minimum:

— machining equipment (for machined seals, as applicable);

— Molding and curing equipment; and

— test and inspection equipment.

Process Control—Elastomers 5.4.2

5.4.2.1 Procedure Requirements—General

The elastomer seal manufacturer shall maintain a documented procedure for each of the processes listed below:

— calibration of temperature controllers, pressure gauges, and monitoring equipment;

— designated preparation descriptions and weights with tolerances;

— process to keep material clean, identified, and free from contamination;

— time and temperature with tolerances and verification method; and

— bill of materials, including materials to be used and their quantities.

5.4.2.2 Mixing

Mixing equipment shall be calibrated and maintained, and comply with the requirements of the compound mixing specified in documented internal standards. The elastomer seal manufacturer shall have adequate storage for in- process, in-transit, and un-vulcanized elastomer compounds. Storage requirements shall be in accordance with the elastomer seal manufacturer’s documented procedures.

5.4.2.3 Molding and Curing Molding and curing capability is required, as appropriate, for the manufacturing processes employed in the manufacture of elastomers. Molding and curing operations shall be performed in accordance with the elastomer seal manufacturer’s documented procedure(s) of the following, as necessary:

— compression press loading instructions;

— transfer press molding instructions;API St 20L pdf download.API St 20L:2018 pdf free download