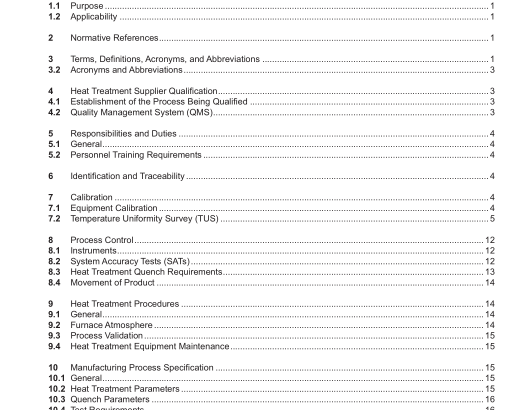

API 20N:2019 pdf free download.Heat Treatment Services—Continuous Line for Equipment Used in the Petroleum and Natural Gas Industry

The heat treatment supplier shall establish the type of instruments they use in the operation of their furnaces. The type of instruments being used will have a direct impact on the survey frequency. See Table 2 and Table 3. Permitted interval extensions are listed in Table 4. If the temperature uniformity is not within the tolerances stated herein, the cause of the deviation shall be determined and documented. Corrective action shall be taken, and the equipment shall not be used for additional processing until a new survey has been performed and meets requirements. This failure data shall be kept as a record along with the actions taken to correct the reason for the failure. 7.2.4 Probe Method Continuous furnaces may be surveyed with TUS sensors that are inserted through the side walls, hearth, or roof of the work zones. The heat treatment supplier shall establish and defne the actual work zones and work zone volume of each furnace. The number of the TUS sensors for this method is dependent upon the size of the work zone. Reference Table 1 for the number of sensors required. The location of the sensors is dependent upon the work zone volume as follows:

a) For work zone volumes greater than 3 ft 3 (0.085 m 3 ), eight TUS sensors shall be located at the corners, and one at the center. If the work zone is cylindrical shaped, three TUS sensors shall be located on the outside diameter, 120 degrees apart. One TUS sensor shall be located in the center, and the other two shall be located to best represent the qualifed work zone.

b) For work zones greater than 225 ft 3 (6.37 m 3 ), the additional sensors required by Table 1 shall be uniformly distributed to best represent the qualifed work zone. c) Each of the inserted TUS sensors shall be within 3 in. of the locations described above.

TUS survey requirements for the probe method shall be as follows:

1) For austenitizing furnaces, the survey shall be done within ±150 °F (83 °C) of the normal operating temperature range mid-point for that furnace. The normal operating range for the austenitizing furnace shall be documented.

2) For tempering furnaces, the survey shall be done at the normal operating temperature range for that furnace. The normal operating range for the tempering furnace shall be documented.

3) The survey temperature shall be conducted within a range of the lowest operating temperature to plus 300 °F (167 °C) and at the highest operating temperature minus 300 °F (167 °C). If the difference between the lowest and highest temperature range is less than or equal to 300 °F (167 °C), only one temperature survey is required.

4) Readings shall be taken every 2 minutes which would include, one controlling, monitoring, or recording sensor in each surveyed zone shall be taken, for a total survey time of 30 minutes minimum once the zone temperature has stabilized.

5) Continuous furnaces that are used for austenitizing or normalizing shall meet a temperature uniformity of ±25 °F (±14 °C). 6) Continuous furnaces that are used for tempering or stress relieving shall meet a temperature uniformity of ±15 °F (±8 °C).

7) The heat treatment supplier shall establish the type of instruments they utilize in the operation of their furnaces. The type of instruments being used will have a direct impact on the survey frequency. See Table 2 and Table 3.

8) Permitted interval extensions are listed in Table 4. If the temperature uniformity is not within the tolerances stated herein, the cause of the deviation shall be determined and documented. Corrective action shall be taken, and the equipment shall not be used for additional processing until a new survey has been performed and meets requirements. This failure data shall be kept as a record, along with the actions taken to correct the reason for the failure.API 20N pdf download.API 20N:2019 pdf free download