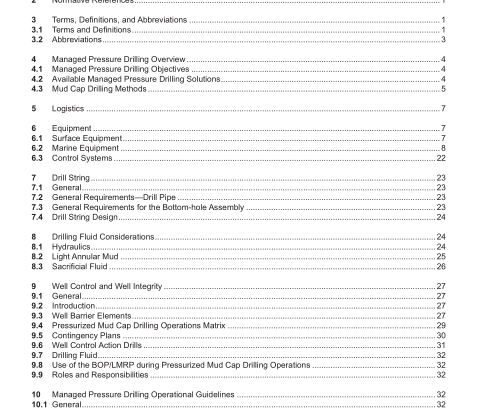

API 92P:2019 pdf free download.Managed Pressure Drilling Operations — Pressurized Mud Cap Drilling with a Subsea Blowout Preventer

4.3 Mud Cap Drilling Methods

4.3.1 General The term “mud cap drilling” is often used to describe drilling methods where there are no returns to surface. Sections

4.3.2 through 4.3.5 comprise a partial list of some of the more common methods that are sometimes referred to as mud cap drilling. 4.3.2 Blind Drilling Blind drilling is a drilling method in which fuid is pumped down the drill string with no returns up the annulus. Little, if any, fuid is pumped down the annulus. It is called blind drilling because there is no way to reliably ascertain the precise downhole conditions unless or until returns come to surface. EXAMPLE Drilling is continued after a total loss of returns. It is called “blind” because no effort is made to keep the annulus full or to maintain contact with or even monitor the fluid level in the annulus. This means there is no way to detect an influx from the formation until either gas migrates through the annular fluid and reaches the surface, or enough influx occurs to lighten the total annular column to the point that the well can flow to the surface. Blind drilling is primarily employed in situations where total losses make it impossible to circulate any fluid to the surface, and there are no productive formations exposed to the wellbore. This method is not covered by this document.

4.3.3 Continuous Annular Injection Continuous annular injection is a drilling method in which fuid is pumped down the drill string, as well as the annulus, continuously. EXAMPLE Fluid is pumped down the drill string to clean and cool the bit and operate the motor, MWD, etc., and additional fluid is continually pumped down the annulus at a rate high enough to overcome formation fluid migration velocity up the hole and keep everything going into the formation. If the formation pressure and annular injection friction pressure combined are less than the hydrostatic pressure of the fluid being pumped down the annulus, there will be no annular pressure at the surface (floating mud cap). If the hydrostatic pressure of the annular fluid is less than the combination of formation pressure and annular injection friction pressure, there will be positive surface annular pressure (pressurized mud cap). This method is not covered by this document.

4.3.4 Floating Mud Cap Drilling Floating mud cap drilling is a method in which the hydrostatic pressure of a full column of annular fuid is higher than the sum of formation pressure and injection friction, so the fuid level remains below the surface or foats. EXAMPLE With a subsea BOP stack, it is possible to monitor the fluid level in the riser with either a pressure sensor on the riser or by filling one of the choke or kill lines with a fluid that is light enough to maintain a column all the way to the surface and with some surface shut-in pressure. Using either of these pressure-monitoring techniques makes it possible to use the principles of PMCD. However, due to changes in wellbore geometry, applying PMCD methods with a fluid level that can rise and fall requires much more complex calculations than are required if there is a static fluid column all the way to the surface.

For example, a given volume of formation fuid that migrates (due to differences in density with the annular fuid) above the top fracture causes a signifcantly different reduction in the hydrostatic pressure at the top fracture than it does at the BOP stack. The differences can be calculated, but the calculations are more complicated than with a static fuid column. This method is not covered by this document.

4.3.5 Pressurized Mud Cap Drilling (PMCD) Pressurized mud cap drilling is a drilling method in which the annulus is completely flled to the surface with a fuid whose hydrostatic pressure is slightly lower than formation pressure, and the resulting annulus shut-in surface pressure is the difference between formation pressure and the hydrostatic pressure of the annular fuid (see Figure 1 and Figure A.1 in Annex A).API 92P pdf download.API 92P:2019 pdf free download