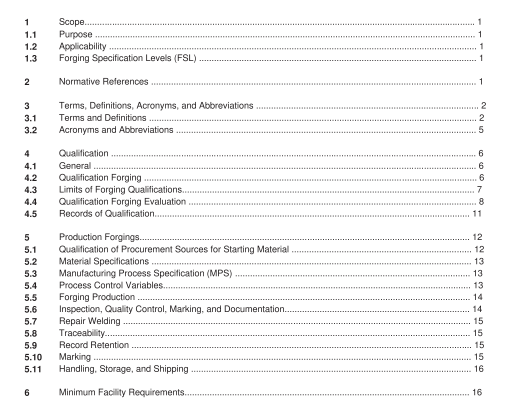

API 20B:2020 pdf free download.Open Die Shaped Forgings for Use in the Petroleum and Natural Gas Industry

5 Production Forgings

5.1 Qualification of Procurement Sources for Starting Material

5.1.1 Only melt source facilities that are approved by the forging manufacturer shall be used to supply starting material such as billet or ingot material. The forging manufacturer shall have a documented procedure, fully implemented, for qualifying starting material suppliers for each specific size and grade of starting material. The approval process shall be based on both a quality assurance and a technical evaluation. The approval process shall establish the methodology by which the starting material supplier will be evaluated on an ongoing basis to maintain their status as an approved material supplier.

5.1.2 The maintenance of an acceptable quality program, such as an ISO registration, is not sufficient by itself to satisfy the requirements of

5.1 .1 . Documented evidence that a starting material supplier has a historical and ongoing technical capability of producing

a) materials meeting this specification, and who has proven, implemented procedures and capabilities in place to consistently produce acceptable product, is a minimum requirement. Options for the technical approval of a starting material supplier include one or more of the following.

b) material supplier with a minimum of one-year experience. Demonstration of acceptable experience shall include tests/inspections, quantity of material received, nonconformance analysis, etc.; on-site technical audit at scheduled three-year intervals. A new starting material supplier shall be subject to an on-site technical audit, which includes the controls addressed in 5.1 .3.

5.1.3 The forging manufacturer is responsible for ensuring that a starting material supplier has implemented controls addressing the following, when applicable, for each size and grade of starting material ordered:

— chemistry controls;

— hydrogen controls;

— melting practice controls;

— teeming practice and ingot mold controls;

— hot work practice controls (method of forging, amount of reduction, forging temperature, etc.);

— cooling rate and method controls;

— ingot/billet cropping controls;

— starting material inspection and acceptance criteria (cleanliness requirements, limitations on porosity or inclusions, grain size, secondary phases, microstructure, macrostructure, etc.);

— material contamination controls (e.g., mercury, radioactivity).

5.2 Material Specifications

5.2.1 Starting material requirements shall be documented in the form of material specifications. Material specifications shall be developed by the forging manufacturer or the purchaser. Material specifications shall include, at a minimum:

— material grade, including element chemistry ranges;

— melting practices and ladle refinements;

— forging reduction range, if applicable;

— acceptable cleanliness level range, as required by applicable FSL;

— acceptable inspection practices and criteria.

5.2.2 The forging manufacturer shall document acceptance of incoming starting material to the requirements of the material specification prior to use for production of forgings.

5.3 Manufacturing Process Specification (MPS)

The forging manufacturer shall prepare a manufacturing process specification (MPS) to include, at a minimum,the material specification and the general variables listed in 5.4.1 and the heat treat parameters listed in 5.4.2. As part of the MPS, the forging steps shall be shown detailing initial and final dimensions during forging for each step of the forging process. This will also include documentation of the heat or reheat temperature ranges required for each hot work reduction step in a drawing and written documents.

5.4

Process Control Variables

5.4.1 General Variables

The following are general process control variables for the production of qualified forgings:

— size of starting material, cut weight, and tolerances;

— evaluation process used for incoming material and for determining cropped length of starting material;

— hydrogen flake-control method (bake-out, slow cool, etc.), if applicable;

— hot-working temperature range;

— overall hot work ratio from starting material;

— description of each forging operation, including general product configuration at the beginning and end of each different type of hot-work or forging operation and hot-work ratio for each step;

— acceptable forging equipment for production;

— inspection requirements;

— NDE, if applicable.

5.4.2 Heat Treat Parameters

The following are heat treat parameters, as applicable:

— furnace loading diagram, orientation, and spacing of production parts;API 20B: pdf download.API 20B:2020 pdf free download