API TR 981:2021 pdf free download.Thermal Expansion Under Load and Creep of Refractories—An Evaluation and Comparison of Testing Methods

1.1 This report documents the results of thermal expansion under load (TEUL) and creep in compression testing conducted by ASTM C832 and DIN 993–9 (same test as ISO 3187).

1.2 The prime objective for this study is to determine if one or both tests should replace the ASTM C16 method. ASTM C16, modifed from 1.5-hour to 100-hour hold, has been widely used to qualify brick for sulfur reaction furnace use. In addition to deformation after 100 hours, the creep tests will provide additional information of TEUL and evidence of mineralogical changes during their early life cycle in process operation.

1.3 The second objective for this study is to better defne a refractory specifcation protocol for premium brick used at high temperatures while supporting a load. Hold temperature in this testing was 1600 °C (3000 °F). This temperature is designed to simulate operating conditions of oxygen-boosted thermal reactors, as well those occurring during over-temperature excursions. 1.4 Orton Memorial Laboratory was selected to do all testing, as this laboratory can test both DIN and ASTM specimens in the same furnaces. Orton used a laser non-contact measurement method for both the ASTM and DIN samples. This allowed an evaluation only of the laser method while still facilitating evaluations of diferences in heating rates, applied compressive load, and hold-time durations.

2 Reference Documents

M. K. Ferber, A. A. Weresczak, and J. G. Hemrick, “Final Technical Report – Compressive Creep and Thermophysical Performance of Refractory Materials,” ORNL/TM-2005/134, Oak Ridge National Laboratory (2006).

S. Jin, H. Harmuth, and D. Gruber, “ Compressive Creep Testing of Refractories at Elevated Loads – Device, Material Law, and Evaluation Techniques,” Journal of the European Ceramic Society, 34 ( 2014) 4037-4042.

O. Buyukozturk and T. Tseng, “ Thermomechanical Creep Behavior of Refractory Concrete Linings,” Journal of the American Ceramic Society, 65 [6] ( 1982) 301-307.)

S. Samadi, S. Jin, D. Gruber, H. Harmuth, and S. Schachner, “ Statistical Study of Compressive Creep Parameters of an Alumina Spinel Refratory,” Ceramics International, 46 ( 2020) 14662-14668. 3 Background

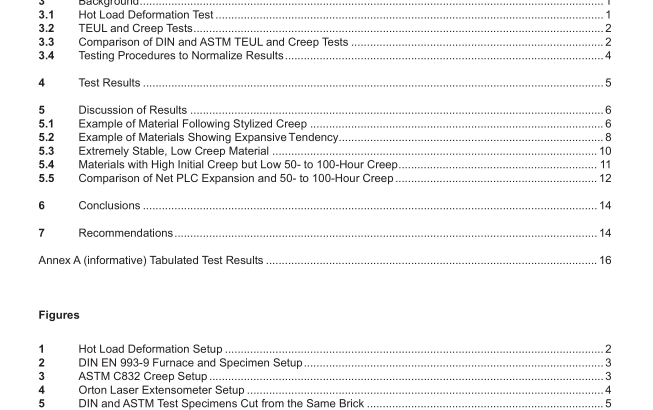

3.1 Hot Load Deformation Test The ASTM C16 hot load deformation test is a long-standing standard used to screen brick and shapes for use in sulfur reaction furnaces. In this test, bricks are placed in a furnace and loaded as in Figure 1.

The test bricks are measured at ambient temperature before and after heating to determine a net permanent linear change. Previous investigators have shown the short 1.5-hour duration under load at the test temperature and volume changing mineralogical transformations can severely limit the usefulness of this test for high-temperature SRU applications.

3.2 TEUL and Creep Tests In both the ASTM C832 and DIN E993-9 creep tests, the specimens are loaded and heated to the temperature, where heating stops and hold time begins. Dilation data are collected during the entire heat cycle, including controlled heating/cooling rates and fnal hold-time duration. In addition to hot load deformation after testing, the point of initial defection (T max or T 0 ), the thermal expansion under load, and creep rate is determined. This, therefore, provides much more additional data for engineering design as compared with the simple hot load test. In addition, Orton kept the output going as the specimens cooled back down to room temperature. In this testing program, the fnal hold temperature was 1650 °C (3000 °F) for 100 hours.

3.3 Comparison of DIN and ASTM TEUL and Creep Tests While ASTM C832 AND DIN EN 993-9 have many similarities, there are key diferences between the tests, as shown in Table 1.

3.4 Testing Procedures to Normalize Results A total of 15 commonly used high-temperature brick products for SRU applications were tested via ASTM C832 and DIN EN 993-9 at the Orton Materials Testing and Research Center in Columbus, Ohio. Because of similarities between the tests, all four of their furnace test units were designed to test both ASTM prism and DIN cylindrical specimens using the diferent loads and heating cycles required in the standards, as defned in Table 1.API TR 981 pdf download.API TR 981:2021 pdf free download