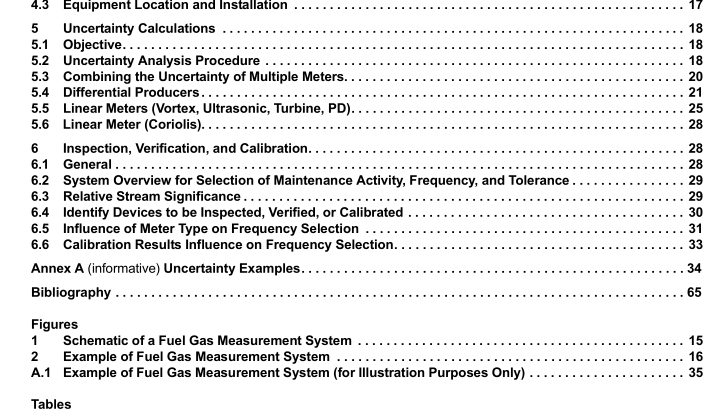

API TR 2571:2011 pdf free donwload.Fuel Gas Measurement

3 Performance Characteristics and Measurement by Meter Type

3.1 General The primary purpose of a fuel gas meter for any application is to measure the flow. The uncertainty of measurement depends on the measurement equipment selected for the application, proper installation of the equipment, the ability to inspect, verify, or calibrate the various measurement system components, and the frequency of those maintenance activities.

The performance of the meter may also depend on the piping configuration and compensation for variability of operating pressure, temperature, and fluid composition. It is important to recognize individual influence parameters and their effect on the measurement.

Since the principle of operation and differing influence parameters have varying degrees of influence by meter type, it is important to identify and define the significant influence factors for the meter to determine the total or combined measurement uncertainty. For “less than ideal installations” where the installation effects (e.g. insufficient straight lengths) are not defined in industry standards (e.g. API MPMS Ch. 14.3/AGA Report No. 3), the manufacturer should be consulted or alternate means considered to quantify uncertainty. Table 1 summarizes the effects of major influence parameters for different meter types.

All parameters that significantly contribute to the measurement uncertainty should be identified and quantified. Any influence parameter that can change should be periodically checked or verified to ensure its contribution to measurement uncertainty remains within the allowable or desired limits. The verification frequency is typically established by historical data or established experience of the industry as detailed in Section 6. All inspections, verifications and calibrations should be appropriately documented. A brief description of the operating principle, design features, and parameters that affect the measurement uncertainty of the fuel gas flow meters commonly used by the industry are detailed in this section.

3.2 Differential Pressure Type Flow Meters

3.2.1 General A differential pressure type flow meter is also referred to as a head type flow meter. The principle of operation of a differential pressure type flow meter is based on the physical law of conservation of energy. The primary element of a differential pressure device causes the fluid velocity to change. The differential pressure measured between two specific locations of the meter is a square root function of the flow rate. Differential pressure producers are sensitive to the flowing density for mass measurements and to the flowing and base densities for volumetric measurements. Hence, the flow rate measurement by differential pressure flow meters is sensitive to variations in fluid composition, compressibility, and flowing temperature and pressure. The square root relationship between velocity and measured differential pressure restricts the turndown of differential pressure producers.

This limitation may be reduced but not eliminated through the use of multiple differential pressure transmitters or transmitters with performance suitable for the range of differential pressures to be measured. The primary element should be designed so that it will produce a differential pressure of sufficient magnitude such that the overall measurement uncertainty is acceptable.

Some of the differential pressure devices used in the industry to measure fuel gas are:

a) orifice flow meter;

b) nozzles;

c) venturi;

d) cone;

e) multiport averaging pitot;

f) wedge;

g) variable area meter;

h) pitot and pitot-static tube.

Table 2 lists the significant influence parameters applicable to all differential pressure meters, their relative importance, and the recommended inspection or performance verification activities associated with each parameter. Table 3 through Table 7 list additional influence parameters applicable to specific differential preessure meter types.

3.2.2 Orifice Flow Meter The primary element of an orifice flow meter is a plate with a hole and the differential pressure across the plate is measured to determine the flow rate. Typically, an orifice plate in fuel gas service is installed between two flanges, so the flow has to be interrupted to remove the plate from the line. There are specially designed dual-chamber orifice fittings that allow removal of the orifice plate from the line without interrupting the flow. Paddle plates with proper labeling provide the opportunity to confirm that the orifice bore dimension, plate type and direction of installation are correct.API TR 2571 pdf download.API TR 2571:2011 pdf free donwload