API TR 17TR9:2017 pdf free download.Umbilical Termination Assembly (UTA) Selection and Sizing Recommendations

4 Functionality and Distribution of Umbilicals

4.1 Umbilical Functionality Functionality is generally limited by the actual umbilical specification rather than the UTA size. The functionality versus umbilical limitations is evident very early in the umbilical design process. Once the final umbilical design specification is reached, then the design of the UTA must be fully optimized to minimize external dimensions and the overall weight of the UTA (including the STI and BSR/bend restrictor weights). An important consideration to fulfill the requirements of this document (also see API 1 7TR1 0) is enabling precise routing of functions within the UTA by having well-designed cable and fluid core distribution routes.

4.2 Subsea Distribution Unit (SDU) SDUs can substantially reduce the overall UTA dimensions by encompassing the distribution paths and outlet ports. It is acknowledged a separate SDU may have an impact on the overall manufacturing cost in order to connect the units together, but the additional design and manufacture costs of separate UTA and SDU arrangements should not be the sole reason for opting for an all-encompassing UTA. Factors such as complicated handling, packing, transporting, increased installation costs, elevated risk of installation damage, and possible replacement of an umbilical with subsequent schedule impact must be thoroughly analyzed and assessed to make an informed decision about the split or combined arrangement of UTA and SDU.

These risks should be evaluated against the consequences associated with using a separate SDU arrangement, such as additional equipment lead time, additional installation time, and the risk of additional subsea leak paths. The application of this document should be from the inception of the umbilical manufacturer’s initial design. Subsequently, the UTA designers should interface closely with highly experienced installation engineers who know installation possibilities, lay spread, and vessel specifications.

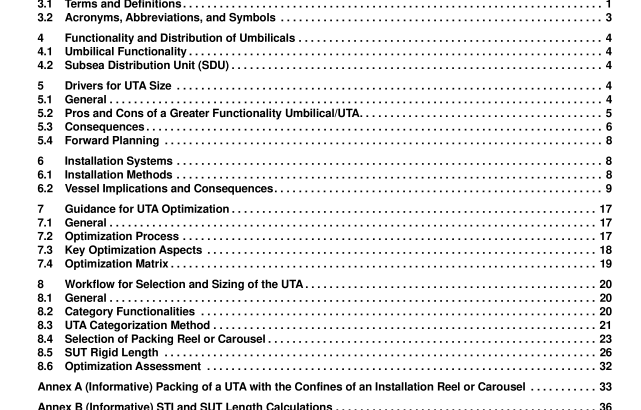

Figure 1 shows the optimum interfacing of relevant parties who will play a part in achieving a successful umbilical/UTA installation project. The intent with describing these project stages is to clarify when within the umbilical project timeline each umbilical termination size reduction (UMSIRE) document should be referenced and the interested parties that should be involved in discussions during each stage.

5 Drivers for UTA Size

5.1 General The trend of increasing functionality of topside, subsea, and downhole equipment over the past decade has created increasing requirements for additional fluid, electrical, and optical lines to be routed from the platform to the subsea equipment. This has resulted in a greater number of functionalities required through control umbilicals and consequently the UTAs. There is competition for space between umbilicals and production risers. If it is assumed that one large umbilical is more space efficient than multiple smaller umbilicals, then larger umbilicals are generally the best option.

5.2 Pros and Cons of a Greater Functionality Umbilical/UTA General

5.2.1 Although it is widely acknowledged that increased functionality, size, and weight of the UTA poses challenges with installation, there are several important drivers and advantages of using umbilicals/UTAs with greater functionality. If increased functionality is balanced correctly with consideration of installation requirements and potential difficulties, this may certainly outweigh the option with reduced functionality. This document and 1 7TR1 0 will support the design evaluation process by taking into account the pros and cons of having a higher-functionality UTA and result in a robust outcome with due consideration of risks versus costs.

5.2.2 The main advantages of a higher-functionality umbilical/UTA are as follows:

— more compact subsea field layout in otherwise congested areas where multiple umbilicals may result in additional complexity and higher risk;

— less vessel time requiring subsequent installs, fewer vessels used during mobilization, does not require second SDU for functionality, decrease number of flying leads;

— spare philosophy for future tie-in to new step-outs, which are in approved but deferred future field architecture;API TR 17TR9 pdf download.API TR 17TR9:2017 pdf free download