API TR 17TR15:2016 pdf free download.API 17H Hydraulic Interfaces for Hot Stabs

If plastic components are selected for use on the male ROV hot stab, the designer shall consider the short- and long- term effects of seawater exposure, including potential dimensional changes and swelling of plastics caused by absorption of seawater that may prevent the hot stab from being extracted from the receptacle. The required stab force should be kept as low as possible.

The required stab force should be verified and documented by the hot stab manufacturer. Hot stab applications utilizing unsecured hoses can introduce separation forces into the system. In these applications, it is recommended to include a mechanical locking feature that will retain the male hot stab and prevent separation from the female receptacle.

4.5 Mounting Considerations Sufficient space shall be provided around the female receptacle to ensure full engagement of the male stab and for the removal of any debris from the receptacle.

The recommended envelopes are shown in the figures and drawings. The hot stab female receptacle should be mounted in the horizontal plane where possible to prevent debris from collecting in the receptacle.

A pressure-retaining blanking (or dummy) male stab is recommended to be inserted into the female receptacle subsea when the hot stab is not being utilized, unless using a pressure-retaining blanking (or dummy) male stab will be detrimental to equipment or application.

The blanking (or dummy) male stab provides seal surface protection from calcification, debris, and marine growth, as well as acting as a secondary barrier to the hydraulic system.

A non- pressure-retaining blanking (or dummy) male stab can also be utilized, but will not act a secondary barrier to the hydraulic system. Where blanking (or dummy) male stabs are used, a parking slot can be provided for parking the blanking (or dummy) hot stab. Lanyards can be used to attach blanking (or dummy) hot stabs to subsea equipment to prevent loss when removed. It is important that lanyards are of sufficient length that they do not inhibit ROV manipulator operation.

When installing the hot stab receptacles onto ROV interface panels, the face of the female receptacle should be protruding above the outer surface of the ROV panel. If the receptacle is mounted to the inner surface of the ROV interface panel, the panel should be no greater than 0.75 in. (20 mm) thick with a free access area large enough to accommodate the male hot stab including the associated hydraulic fittings. If the mounting flange on the receptacle utilizes a split flange design, then it should utilize an anti-rotation feature to prevent the receptacle from rotating.

4.6 Operations Hot stabs may be operated by manipulator, TDU, deployment tool, or diver. Grab bars should be positioned to allow linear actions of ROV manipulators when inserting hot stabs or blind stabs, which will reduce the risk of seal damage during hot stab manipulation.

4.7 Materials in Design Material selection should be decided by the manufacturer. Material selection should follow EEMUA Publication 194 in conjunction with the following considerations.

a) Materials should be seawater corrosion resistant alloys and/or protected by a CP system. Design lifetime and cathodic protection must be assessed during material selection.

b) Galling between mating parts should be carefully assessed and mitigating actions taken. Mitigating action(s) include the selection of non-galling materials or dissimilar metal used for mating parts. c) Materials should have the ability to withstand typical ROV impact loads as per API 17H.

NOTE Nitronic 50, Nitronic 60, AISI SS 316, Aluminum Bronze, Inconel 625, duplex, and super duplex are typical materials that have been used for subsea hot stab applications.

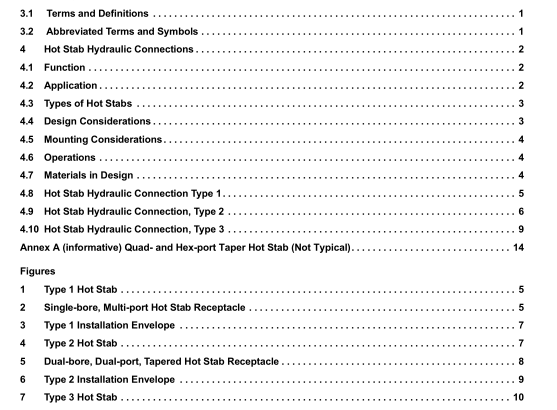

4.8 Hot Stab Hydraulic Connection Type 1

The Type 1 hot stab is a multi-port design with single stab seal diameter. Different seal diameters and number of ports can be produced. Internal bore and hydraulic ports can be optimized for each design based on design pressure, interface requirements, and number of ports. The Type 1 hot stabs typically cover hot stabs with one to six individual ports.

Figure 1 shows a typical example of a Type 1 hot stab. Figure 2 shows all the internal interfaces dimensions of the Type 1 multi-port hydraulic interface, including seal surface areas. Specific dimensions for each bore size can be found in Table 1.API TR 17TR15 pdf download.API TR 17TR15:2016 pdf free download