API TR 10TR4:2008 pdf free download.Selection of Centralizers for Primary Cementing Operations

Eighty-three percent standoff may or may not be sufficient for a quality cementing job. The standoff obtained by rigid centralizers may not be adequate for effective mud removal and zonal isolation.

Conversely, bow-spring centralizers may not be able to withstand the side loads exerted in a wellbore thereby limiting the degree of standoff that can be designed. It is important to remember at this point that 67 % standoff was never a recommended level by API/ISO. It is simply a means to help manufacturers produce API-quality centralizers (bow-spring).

It is also noted that in all the cases in Table 2, the minimum gap between the casing and the wellbore at the centralizer is 0.25-in., assuming embedment of the centralizer at the wellbore is negligible. Another important point is whether the centralizers are installed on the casing before the actual size (caliper) of the open hole is known (hole size is often estimated from offset wells). In this situation, if the actual hole turns out to be enlarged, it might be too late to change the previously selected centralizer type.

Bow-spring centralizers for this example can have a maximum OD of over 1 3-in., with a compressed OD of as low as 8.231 -in. (less than the previous casing drift diameter). Thus, for such a well with an enlarged hole, bow-spring centralizers may provide higher degrees of standoff as long as the running and normal forces are acceptable.

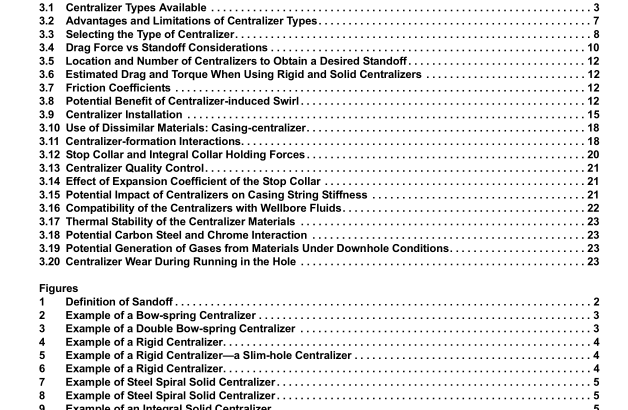

3.5 Location and Number of Centralizers to Obtain a Desired Standoff Calculating the location and number of solid and rigid centralizers to obtain a given desired standoff is easier than for bow-spring centralizers because the restoring force of the centralizer is not a factor in the calculations. At the centralizer, the standoff is simply calculated using the previously given Equation 1 . This equation assumes that the centralizer is in contact with the formation at some point and that there is no embedment of the centralizer into the formation. Between centralizers, the casing sag point should be estimated using the equations given by API and ISO documents dealing with recommended practices for the use of bow-spring centralizers (ISO 1 0427-2). For calculations of casing sag the equations used for bow-spring centralizers apply, with the exception that solid and rigid centralizers do not flex due to the normal forces.

3.6 Estimating Drag and Torque When Using Rigid and Solid Centralizers API and ISO documents (for example, ISO 1 0427-2) contain the needed formulas to calculate the normal forces for a given hole-casing geometry based upon the vector sum of the weight and the tensile components. Factors affecting the calculations include casing weight, mud and cement slurry densities, well inclination and dogleg severity. After the normal forces are calculated up and down the casing for the given well configuration, friction forces can be calculated by multiplying the normal forces by the estimated dimensionless friction factor. The total drag can then be estimated by adding up the calculated localized friction forces. Similarly, assuming the casing rotates inside the centralizer (centralizer is fixed against the formation) localized torque components are estimated using the calculated normal forces and the estimated friction factor. Total torque at the surface is estimated by adding up all the torque components. These calculations require a computer simulator, particularly for complicated well trajectories and severe dogleg sections.

3.7 Friction Coefficients The value of the friction coefficient for a centralizer is influenced by the material used to manufacture the centralizer, the type of centralizer (bow-spring, rigid and/or solid), the blade orientation, the mud system used (level of lubricity) and the formation. Friction coefficients are dependent on the mud type and its additives (including lubricants). Typical field-used friction coefficients are given below.API TR 10TR4 pdf download.API TR 10TR4:2008 pdf free download