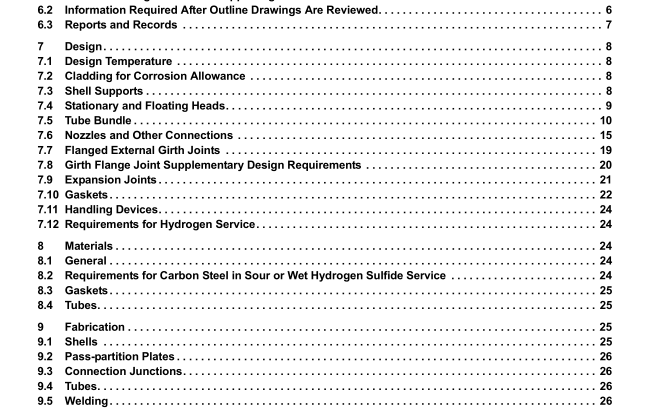

API STD 660:2015 pdf free download.Shell-and-Tube Heat Exchangers

4.11 The purchaser shall specify if the shell or tube side is in hydrogen service.

4.12 For single tube pass floating-head and all fixed tubesheet heat exchangers, the purchaser shall specify the data required to determine the need for an expansion joint. This shall include all intended operating conditions defined on the expansion joint datasheet shown in Annex C.

5 Proposal Information Required

5.1 For each heat exchanger unit, the vendor’s proposal shall include completed datasheets, such as those given in Annex C, or if a datasheet is included in the inquiry, a statement indicating complete compliance with that datasheet.

5.2 The vendor’s proposal shall include sketches that are sufficient to describe the construction for the following, if provided:

a) design features that are not fully defined by the nomenclature in TEMA, Section 1;

b) an annular distributor;

c) floating-head designs which include a tail-pipe and expansion joint;

d) expansion joints for fixed tubesheet exchangers. Including the location, material and type;

e) high pressure closure including channel to tubesheet attachment, shell to tubesheet attachment, and welded diaphragm or welded lip-seal construction.

5.3 The proposal shall include a detailed description of all exceptions to the requirements of the purchaser’s inquiry.

5.4 For stacked heat exchangers, the vendor shall supply the following components, unless otherwise specified by the purchaser:

a) bolts, nuts, and gaskets for interconnecting nozzles;

b) shims or spacers and bolting for interconnecting supports.

5.5 The vendor shall provide a separate quotation for the following items, unless otherwise specified by the purchaser.

a) A test component consisting of a test ring and gland, in accordance with TEMA, Figure E-4.13-2 or equivalent, for each heat exchanger or group of similar heat exchangers with floating heads.

b) One spare gasket for each external girth flange, floating-head flange (if applicable), and internal pass-partition flange (if applicable) per heat exchanger.

6 Drawings and Other Required Data

6.1 Outline Drawings and Other Supporting Data

6.1.1 The vendor shall submit, for review by the purchaser, outline drawings for each heat exchanger unit. The drawings shall include at least the following information:

a) service, item number, project name and location, purchaser’s order number, vendor’s shop order number, and other special identification numbers;

b) design pressure, test pressure, design temperature, minimum design metal temperature, and any restriction on testing or operation of the heat exchanger;

c) maximum allowable working pressure (MAWP) in the corroded condition and at the design temperature for the shell side and tube side;

d) connection sizes, location, orientation, projection, direction of flow and, if flanged, the rating and facing or, if welded to the connecting piping, the weld bevel preparation;

e) coupling sizes, rating, and orientation;

f) dimensions, orientation and location of supports, including bolt holes and slots, and the stacking arrangement;

g) overall dimensions of the heat exchanger;

h) tube bundle removal clearance;

i) mass of the heat exchanger, empty and full of water, and of removable components with a mass greater than 25 kg (60 lb), (e.g. removable tube bundle, channel, channel cover, and shell cover);

j) specified corrosion allowance for each side of the heat exchanger (see A.3.1);

k) references to the applicable code and the purchaser’s specification;

l) requirements for postweld heat treatment;

m) requirements for non-destructive examination (NDE);

n) requirements for material impact testing;

o) requirements for surface preparation and painting;

p) gasket materials;

q) insulation thickness;

r) location of expansion joints, annular distributors, and any other special components or closures;

s) location and orientation of nameplates, lifting lugs, grounding clips or other attachments;

t) location of the center of gravity of the heat exchanger (empty and full of water);

u) forces and moments on connections as specified by the purchaser (see 7.6.9);

v) material specifications and grades for all components.

6.1.2 The vendor shall submit flow-induced vibration analysis, if specified by the purchaser. See A.3.2.

6.1.3 The vendor shall recommend the tools required for the assembly and maintenance of the heat exchanger. If torquing or tensioning of bolts is required, the vendor shall provide applicable procedures.

6.1.4 The review of engineering documents by the purchaser shall not relieve the vendor of the responsibility of meeting the requirements of the purchase order.API STD 660 pdf download.API STD 660:2015 pdf free download