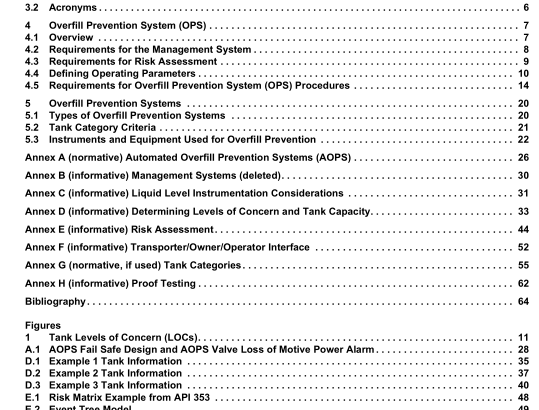

API STD 2350:2020 pdf free download.Overfill Prevention for Storage Tanks in Petroleum Facilities

3.2 Acronyms

AHJ authority having jurisdiction

AOPS automated overfill prevention system

ATG automatic tank gauge

CH Critical High

HH High-High tank level

LAHH High-High tank level alarm

LNG liquified natural gas

LOC level of concern

LOPA layer of protection analysis

LPG liquified petroleum gas

MOC management of change

MOPS manual overfill prevention system

MW maximum working level

OPS overfill prevention system

PHMSA Pipeline and Hazardous Materials Safety Administration

PIC person in charge

PLC programmable logic controller

SCADA supervisory control and data acquisition system

SIS safety instrumented system

WDT watchdog timer

4 Overfill Prevention System (OPS)

4.1 Overview

The likelihood and the associated consequences of overfilling a tank vary from one facility to another and even between tanks within a facility. Prevention of tank overfills requires taking into account the following factors:

— awareness and calculation of available tank capacity and inventory;

— careful monitoring and control of product movement and tank level during filling;

— use of reliable instrumentation, sensors, and systems;

— use of human response to manually initiate the termination of flow (MOPS);

— use of automatic tank gauging systems, independent high-level alarms, etc. to address the gaps arising from a risk assessment and risk analysis; and

— use of automated response systems to automatically terminate the flow (AOPS), where appropriate.

Consequently, a comprehensive and flexible approach to overfill prevention is provided in this document. Careful consideration was given to the benefits provided by overfill prevention for tanks in petroleum facilities relative to:

— safety and environmental protection;

— optimization of the workplace and operating practices;

— inspection, testing, and maintenance;

— equipment and system selection and installation;

— safe work practices, emergency procedures, and training;

— management of change programs relative to tank overfill prevention;

— inclusion of current technology and practices related to process control and automated safety instrumented systems.

This allows the owner/operator of each facility to assess the risks and implement appropriate facility-specific or tank specific practices to prevent tank overfills.

The OPS consists of several fundamental components:

a) management system;

b) risk assessment process;

c) operational parameters;

d) procedures (including those for receipt termination) and training; and

e) equipment supporting OPS and its inspection, testing, and maintenance.

4.2 Requirements for the Management System

A management system is the framework of administrative processes and procedures used to enable the owner/operator to fulfill the tasks required to prevent an overfill. A management system is required and shall be documented for conformance with API 2350, but this standard does not specify how to implement nor document such a system. This management system may be integrated with existing safety or environmental procedures or be developed as a stand-alone system. This task is the responsibility of the owner/operator. A properly structured management system provides all the practices and components required for a good OPS and is managed and periodically assessed and updated to keep practices current as people and equipment change. API RP 1173, Pipeline Safety Management Systems, provides some guidance on management systems.

At a minimum, the management system shall address:

a) formal documented operating procedures and practices, including safety and emergency response procedures;

b) competency of operating and maintenance personnel;

c) functional equipment systems, tested and maintained by competent personnel;

d) scheduled inspection and maintenance programs for overfill instrumentation and equipment;

e) systems and procedures to address both normal and abnormal operating conditions;

f) management of change (MOC) process that includes personnel and equipment changes;

g) system to identify, investigate, and communicate overfill near-misses and incidents;

h) system to share lessons learned;

i) follow-up system to address any needed mitigation of circumstances leading to near-misses or incidents;API STD 2350 pdf download.API STD 2350:2020 pdf free download