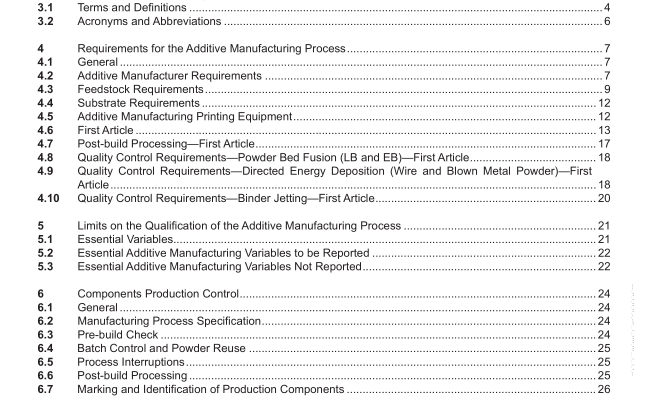

API STD 20S:2021 pdf free download.Additively Manufactured Metallic Components for Use in the Petroleum and Natural Gas Industries

4 Requirements for the Additive Manufacturing Process

4.1 General This standard gives the requirements for three additive manufacturing specifcation levels (AMSL). The AMSLs are numbered in increasing levels of severity from 1 to 3 to refect increasing technical, quality, and qualifcation criteria. This section describes the conditions that, when met, allow the additive manufacturing process to receive the appropriate AMSL classifcation. When additively manufactured metallic components are ordered to an API product specifcation or API product standard, the API product specifcation or API product standard shall take precedence over this standard as long as the requirements of the API product specifcation or API product standard meet or exceed the minimum requirements set forth in this standard.

4.2 Additive Manufacturer Requirements

4.2.1 General For all AMSLs, the additive manufacturer shall implement and maintain required controls to ensure products and services meet specifed requirements and shall conform with the requirements of 4.2 and its subsections.

4.2.2 Additive Manufacturer Quality Management System (QMS)

The additive manufacturer shall establish, document, implement, and maintain, at all times, a QMS and associated processes. The QMS shall be in conformance with either API Specifcation Q1 or ISO 9001.

4.2.3 Quality Control Procedures All quality control activities shall be controlled by the additive manufacturer’s documented procedures, which include appropriate methodology and acceptance criteria. NDE procedures shall be detailed regarding the requirements of all applicable nationally or internationally recognized standards specifed by the additive manufacturer. All NDE procedures shall be approved by a Level III examiner qualifed in accordance with ASNT SNT-TC-1A or ISO 9712 in the specifed discipline. 4.2.4 Technical Review Requirements The additive manufacturer shall maintain procedure(s) to ensure that technical requirements are reviewed prior to acceptance of the order.

The additive manufacturer shall maintain records of this review, including:

— applicable purchaser or governing design and/or construction specifcations/standards;

— deviations from governing design and/or construction specifcations/standards;

— material specifcations;

— acceptance criteria;

— qualifcation of procedures;

— qualifcation of personnel;

— qualifcation of printing equipment;

— outsourced services;

— inspection and testing requirements, including third-party verifcation;

— identifcation and traceability;

— post-processing requirements.

4.2.5 Personnel Training and Competency Requirements

Personnel shall be competent to carry out assigned tasks and responsibilities based on the appropriate education, training, skills, and experience needed to meet product and purchase order requirements. The additive manufacturer shall maintain a written procedure that defnes personnel competency and identifes training and qualifcation requirements.

The additive manufacturer shall identify:

— knowledge and training necessary to address specifc requirements;

— qualifcations required for personnel performing processes that require validation;

— method(s) used to verify the competency of personnel.

The additive manufacturer shall maintain evidence of conformity to the above requirements.

4.2.6 Non-destructive Examination Personnel Requirements

Personnel performing NDE shall be qualifed in accordance with the additive manufacturer’s documented training program that is based on the requirements specifed in the following:

— ISO 9712; or

— ASNT SNT-TC-1A; or

— a national or international standard that is equivalent to ISO 9712 or ASNT SNT-TC-1A.

NDE Level I or Level II personnel shall be qualifed by NDE Level III personnel in the specifed discipline.

4.2.7 Inspection Personnel Requirements

Personnel performing visual inspection for acceptance shall take and pass an annual vision examination in accordance with the additive manufacturer’s documented procedure that is based on the requirements specifed in the following:

— ISO 9712; or

— ASNT SNT-TC-1A; or

— a national or international standard that is equivalent to ISO 9712 or ASNT SNT-TC-1A.

4.2.8 Other Personnel Requirements

All other personnel performing measurements, inspections, or tests for acceptance shall be qualifed in ccordance

with the additive manufacturer’s documented procedures and requirements.

4.2.9 Facility Requirements

The additive manufacturer shall have on-site equipment and personnel to perform the required processes needed to produce the components under the scope of this standard as identifed below:

— equipment to perform required printing activities (excluding post-processing activities);API STD 20S pdf download.API STD 20S:2021 pdf free download