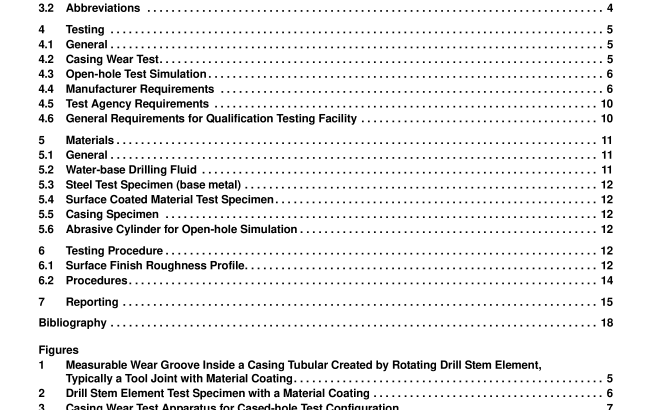

API St 7CW:2015 pdf free download.Casing Wear Tests

4.1 General

While a surface finish of a solid may appear to be very smooth, microscopically small topographical irregularities cover the solid surface. These irregularities are called asperities. Surface roughness is a general geometric characteristic of asperities on a larger scale.

A common measure of average surface roughness, R a , is expressed in units of height. In U.S. customary units, 1 R a is typically expressed in “millionths” of an inch or micro-inch. As two solid surfaces meet and frictionally interface with one another, wear mechanisms such as galling, grinding, machining, or polishing may create wear debris of various shapes and sizes. The rate of material removed per unit of time or distance creates a dimensional change described as a wear rate.

The term coefficient of friction describes the dimensionless ratio of the friction force between two bodies to the normal force pressing these bodies together. Axial friction factor is a related term that describes the ratio of frictional force and contact force between the test specimen and the casing while sliding (not rotating).

Rotational friction factor describes the ratio of frictional force and contact force between the test specimen and the casing while rotating. Three-body abrasive wear is a common occurrence when loose particles are introduced or generated between two contact surfaces. Critical wear groove depth is demonstrated in cases of severe wear, where the entire tool joint specimen diameter may protrude through the casing wall.

4.2 Casing Wear Test

4.2.1 This test method describes laboratory procedures to create a measurable wear groove and classify the wear by determining the amount of material worn away from a casing specimen by means of abrasion. (See Figure 1 .)

4.2.2 The abrasion is created by rotating and reciprocating a drill stem element, test specimen (see Figure 2), against a stationary casing specimen (see Figure 1) at a prescribed side-load (see Figure 3). Additional abrasion is supplied by materials in the drilling fluid continuously circulated during the test procedure. The chief abrasive component within that drilling fluid is 1 00 mesh sand.

4.3 Open-hole Test Simulation

4.3.1 This test method describes laboratory procedures for determining the amount of material worn away from a rotating drill stem element test specimen, by means of abrasion from a counter rotating abrasive cylinder (see Figure 4).

4.3.2 The abrasion is imposed upon the drill stem element, typically a test specimen, by an abrasive element, typically in the shape of a cylinder (Figure 5); and at a prescribed side-load (Figure 6). Some additional abrasion is supplied by materials in the drilling fluid continuously circulated during the test procedure. The chief abrasive component within that drilling fluid is typically 1 00 mesh sand.

4.4 Manufacturer Requirements

4.4.1 Testing to qualify a hardband or material coating shall be performed by a test agency.

4.4.2 The manufacturer shall submit two field-ready specimens of most recent manufacture for testing.

Steel drill stem element test article substrate (base metal) shall conform to material qualification (see 5.3).

Supply traceability documentation with material shall conform to API 5DP.

The manufacturer shall permanently stamp the identification of the material being tested into the specimen wall.

4.4.3 Substantive changes to the material chemistry or application process shall require requalification of thematerial.

4.4.4 The test specimen length and diameter dimensions shall be defined by this standard.4.5Test Agency Requirements

4.5.1 The test agency shall conduct tests in accordance with this standard.

4.5.2 The test agency shall be responsible for assuring itself, the manufacturers and the operators that the testfacility, procedures and forms comply with this standard.

4.5.3 The test agency shall provide or make available for review current documentation to manufacturers oroperators on written request.This shall include, as a minimum, the following:

a) description of the facility, including any limitations on the diameter, length, temperature, load rating, and service ofspecimens may be tested;

b) test procedures and forms actually used at the test facility;

c) procedures for maintenance and calibration of measuring equipment;

d) procedures for making applications for tests,the delivery of specimens,pre- and post-test dimensionalverification, and the initial installation and checkout in the test apparatus;

e) any limitations on the accessibility of the facility (such limitations shall not preclude access to the facility for

inspection by manufacturers or operators for their testing); and

f)any limitations on the receipt of proprietary, competitive, or confidential information.API St 7CW pdf download.API St 7CW:2015 pdf free download