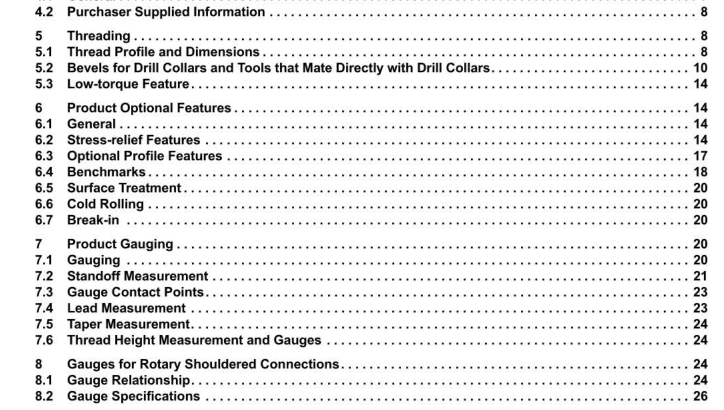

API SPEC7-2:2017 pdf free download.Threading and Gauging of Rotary Shouldered Connections

5.2.2 Purpose of Be v els Bevels on connect ions serve two purposes.

The fi rst is to protect the outer edge of the sea ling face from deformation in the form of mashes and fins. The second is to increase the contact pressure on the sea ling face so as to mini mize leaking and sepa ra tion due to downho le bending Bevel dia mete rs on the same ODs should be of equal size , within manufacturing tolerances , on mat ing pins and boxes to min imize the formation of grooves on the sealing faces. When mismatches of ODs greater than 6. 35 mm (0.250 in.) occur , mismatches of bevel diameters will also occur.

Historically bevel diameters have been calculated every 6.35 mm (0.250 in.) based on 75 % of the shoulder width. This basic calculation is simple and depends only on the outside diameter and counter bore of the connection. Effort has been made to preserve these historical bevel diameters because they are easy to calculate and have worked very well in most cases 5.2.3 Methods to Calculate Bevel Diameters The process is fully described in Annex E.

5.2.4 Other Consideration s Table 8.3 has bevel diameters that cover a range from a suggested minimum 00 to a maximum 00 . For an 00 falling between two listed values , the bevel diameter corresponding to the smaller 00 shall be used. Table 8.3 also contains a reference 10.

The purpose of the reference 10 is to be able to calculate shoulder loads that will not cause the seal face stress on mismatched OOs to exceed the 8MY8 of the product materia l. When the 10 of the pin connection (pin end) that mates directly with it is equal to or greater than the reference 10 , the minimum 00 listed for each connection in Table 8.3 can be mated with the largest 00 listed (or any 00 in between) for that same connection in Table 8.3 and the stress on the seal face will not exceed 1 00 % of 8MY8.

The smallest bevel diameter shown in Table 8.3 is the smallest bevel diameter recommended for each connection to avoid the risk that seal face stress generated by mismatches of OOs may exceed the 8MY8 . If a rotary shouldered connection is used on a product with smaller outside diameter than is listed in the table , the bevel diameter shall be set by agreement between the manufacturer and the purchaser.

Unless otherwise specified , bevel diameter tolerances shall be +0 .4 mm (+0.01 6 in.). 8evel diameters in Table 8.3 shall not apply to products that have specific requirements in API 50P , API 7-1 , 1 80 1 0424-1 , and 1 80 11961 , such as tool joints for drill pipe and HWOP , bits , or boxes that ma te with bits. For drilling equipment outside the scope of these standards , the manufacturer may specify a bevel diameter other than that listed in Table 8 .3.

5.3 Low-torque Feature 8everal connections in larger sizes shall have modified bevel diameters and enlarged face counterbores when used on products with a large outside diameter. This allows the makeup torque to achieve adequate compressive stress on the sealing face while maintaining bending stiffness. These features are shown in Figure 6 , and dimensions in Table 8 .4. These features shall be mandatory above the product diameter indicated in Table 8 .4 .

6 Product Optional Features

6.1 General These features are required only if specified by the product specification (API 50P or 1 80 1 0424-1 or 1 80 1 1 961 ) , or on the product order. 80me of the features noted below may be applied at the manufacturer’s option.

6.2 Stress-relief Features If fatigue failures in connections can be a problem , stress-relief features may be specified. 8tress-relief features are of two basic designs: (1) a groove on the pin and a boreback contour for boxes or (2) a groove on both the pins and boxes. The boreback stress-relief contour is the recommended design for the box connection (box end). However , the box relief groove also has been shown to provide beneficial effects.API SPEC7-2 pdf download.API SPEC7-2:2017 pdf free download