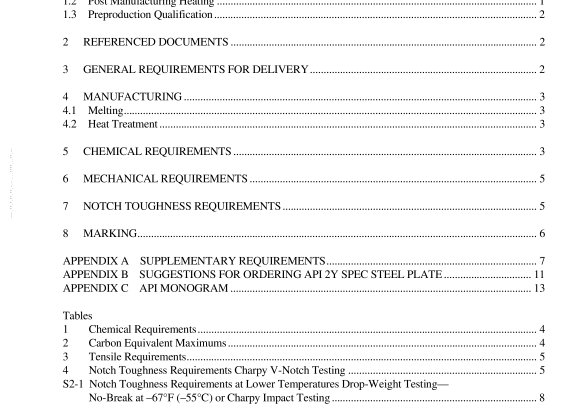

API SPEC 2Y:2006 pdf free download.Specification for Steel Plates, Quenched-and-Tempered, for Offshore Structures

1.1 COVERAGE This specification covers two grades of high strength steel plate for use in welded construction of offshore structures, in selected critical portions which must resist impact, plastic fatigue loading, and lamellar tearing. Grade 50 is covered in thicknesses up to 6 in. (150 mm) inclusive, and Grade 60 is covered in thicknesses up to 4 in. (100 mm) inclusive.

1.1.1 It is intended that steel produced to Grade 50 of the basic API Spec 2Y, without Supplementary Requirements, be at least equivalent in minimum performance and, therefore, in service application, to the corresponding grades listed in Sections 5 through 7 of API Spec 2H and API Spec 2W.

1.1.2 API Spec 2Y steels are intended for fabrication primarily by cold-forming and welding. The welding procedure is of fundamental importance and it is presumed that procedures will be suitable for the steels and their intended service. Because of the characteristic high YS/TS ratio of quenched-and-tempered steels, users may want to consider welding consumables which avoid undermatched weld metal. Conversely, the steels should be amenable to fabrication and welding under shipyard and offshore conditions.

1.2 POST MANUFACTURING HEATING

1.2.1 Due to the inherent characteristics of quenched-and-tempered material, plates manufactured to this Specification cannot be formed or postweld heat treated at temperatures above the tempering temperature used during manufacture without some risk of sustaining irreversible and significant losses in strength and toughness. If warm-forming is to be required, the tensile and notch toughness properties of the finished component shall be verified and the properties shall conform to the requirements of the specification. The plates may be post-weld heat treated at a temperature higher than that used during manufacture, providing the test coupons are subjected to a thermal cycle to simulate such fabrication operations, as described in Supplementary Requirement S9. Verification or simulation is not necessary for heating at temperatures not exceeding 400°F (205°C).

1.2.2 The primary use of these steels is in tubular joints, stiffened plate construction, and other intersections where portions of the plates will be subject to tension in the thickness direction (Z-direction). Supplementary Requirement S4 provides for through-thickness (Z-direction) testing of the plates by the manufacturer and specifies limits for acceptance. Supplementary Requirement S1 provides for ultrasonic examination of the plates by the manufacturer and specifies limits for acceptance.

1.2.3 For applications where through-thickness properties are important but Z-direction testing has not been specified, Supplementary Requirement S5 provides a low-sulfur chemistry intended to reduce the size and number of sulfide inclusions in the plate. Supplementary Requirement S5 is neither a substitute for Supplementary Requirement S4, Through Thickness Testing, nor a guarantee of a minimum level of through-thickness ductility.

1.2.4 The notch toughness requirements specified in Section 7 are suitable for application below water, or above water in areas of temperate climate (14°F [–10°C] minimum service temperature). Cold-formed materials have less toughness due to straining than that of the original flat plates, especially in those areas aged by the attachment welding of stubs and braces. The requirements for plates in Section 7 take into consideration typical losses in toughness due to straining and aging. Supplementary Requirements S7 and S8 deal with the strain-aging problem, and consideration should be given to invoking Supplementary Requirement S7 and/or S8 when the strain exceeds 5% or when (Nitrogen × % strain) exceeds 0.040.

1.2.4.1 For application with lower service temperatures, lower test temperatures should be considered. Supplementary Requirement S2 provides for impact tests at temperatures other than specified in Section 7 or Supplementary Requirement S12. Supplementary Requirement S2.1 provides for Drop-Weight or Charpy V-notch testing at –60°C. Supplementary Requirement S2.2 provides for such testing at temperatures less than –40°C but other than –60°C.

1.3 PREPRODUCTION QUALIFICATION Supplementary Requirement S11 and Section 3 of API RP 2Z, dealing with CTOD testing of the weld heat-affected zone and with resistance to hydrogen cracking, respectively, address problems which are not normally dealt with in a “commodity grade” steel specification. These problems are not unique to Q&T steels, but arise because:

a. Users may be expecting higher performance from Q&T steels than is available with conventional steels (e.g., superior notch toughness), and

b. This is a performance specification which accommodates a variety of different steelmaking practices, rather than a recipe which completely defines all particulars of chemistry, process, and quality control (essential variables). It is intended that Supplementary Requirement S11 shall apply only when specified in advance by the purchaser. In many cases it may be possible to rely on prior data assembled by the steelmaker, provided no essential variables of the process have been changed.API SPEC 2Y pdf download.API SPEC 2Y:2006 pdf free download