API RP 941:2016 pdf free download.Steels for Hydrogen Service at Elevated Temperatures and Pressures in Petroleum Refineries and Petrochemical Plants

3 Operating Experience

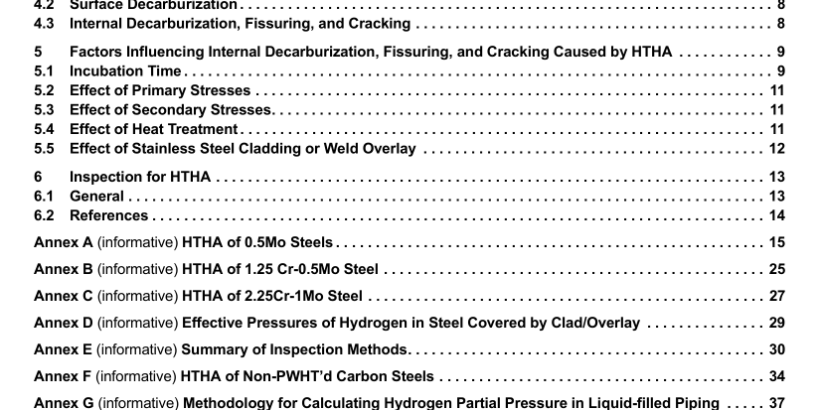

3.1 Basis for Setting Integrity Operating Windows Figure 1 illustrates the resistance of steels to attack by hydrogen at elevated temperatures and hydrogen pressures. HTHA of steel can result in surface decarburization, internal decarburization, fissuring, and cracking, or a combination of these (see Section 4).

Figure 1 gives the operating conditions (process temperature and hydrogen partial pressure) above which these types of damage can occur.

Figure 1 is based upon experience gathered since the 1940s. Supporting data were obtained from a variety of commercial processes and laboratory experiments (see the References to Figure 1). While temperature and hydrogen partial pressure data were not always known precisely, the accuracy is often sufficient for commercial use.

Satisfactory performance has been plotted only for samples or equipment exposed for at least 1 year. Unsatisfactory performance from laboratory or plant data has been plotted, regardless of the length of exposure time. The chemical compositions of the steels in Figure 1 should conform to the limits specified for the various grades by ASTM/ASME. Owners/operators should develop integrity operating windows (IOWs) (as outlined in API 584) to manage risks associated with HTHA by using operational experience presented in this document. Since the original version of Figure 1 was prepared for API in 1949 [1] , further experience has enabled curves for most commonly used steels to be more accurately located. All information relevant to 0.5Mo steels (C-0.5Mo and Mn-0.5Mo) is summarized in Annex A.

The Fifth Edition of this RP also added three data points, which show HTHA of 1.25Cr-0.5Mo steel below the current 1.25Cr-0.5Mo curve. See Annex B for more discussion of 1.25Cr-0.5Mo steel. Annex C gives a similar discussion for 2.25Cr-1.0Mo steel. This Eighth Edition adds 12 data points and a new curve labeled as “Carbon steel (welded with no PWHT)” for HTHA of carbon steel not subjected to postweld heat treatment (PWHT), which is below the carbon steel curve appearing in all previous editions and now labeled as “Carbon steel (non-welded or welded with PWHT).” See Annex F for more discussion on carbon steel welds not subjected to PWHT.

3.2 Selecting Materials for New Equipment

The API Subcommittee on Corrosion and Materials collects data on the alloys shown in all figures or similar alloys that may come into use. Follow the guidance in Annex H for submitting new data. Figure 1 is often used when selecting materials for new equipment in hydrogen service. When using Figure 1 as an aid for materials selection, it is important to recognize that Figure 1 only addresses a material’s resistance to HTHA. It does not take into account other factors important at high temperatures such as:

a) other corrosive species that may be in the system such as hydrogen sulfide;

b) creep, temper embrittlement, or other high temperature damage mechanisms;

c) interaction of hydrogen and stress (primary, secondary, and residual); and

d) synergistic effects such as between HTHA and creep. Temperatures for data plotted in the figures represent a range in operating conditions that in previous editions was stated to be about ±20 °F (±11 °C).

Because of the uncertainty of the actual operating conditions over many decades of operation for data points contained in the curves, users need to understand that Figure 1 is based largely upon empirical experience and from the guidance in API TR 941 [39] .

Therefore, an operating company should add a safety margin, below the relevant curve, when selecting steels.

3.3 High Temperature Hydrogen

Attack (HTHA) in a Liquid Hydrocarbon Phase HTHA can occur in a liquid hydrocarbon phase if it can occur in the gas phase in equilibrium with the liquid phase. For materials selection purposes (using Figure 1), hydrogen dissolved in liquid hydrocarbon should be assumed to exert a vapor pressure equal to the hydrogen partial pressure of the gas with which the liquid is, or was last, in equilibrium. Recent plant experience and testing of field-exposed specimens have shown that HTHA can occur under such conditions [10] .API RP 941 pdf download.API RP 941:2016 pdf free download