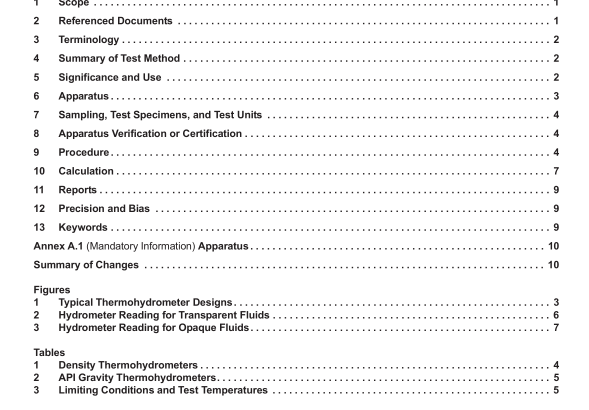

API MPMS 9.3:2012 pdf free download.Manual of Petroleum Measurement Standards Chapter 9.3 Standard Test Method for Density, Relative Density, and API Gravity of Crude Petroleum and Liquid Petroleum Products by Thermohydrometer Method

6.2 Hydrometer Cylinders, clear glass, plastic, or metal. For convenience of pouring, the cylinder may have a pouring lip. The inside diameter shall be at least 25 mm (1 in.) greater than the outside diameter ofthe thermohydrometer used. The height of the cylinder shall be such that the bottom of the thermohy drometer clears the bottom of the cylinder by at least 25 mm (1 in.) when suspended in the sample test portion.

6.2.1 For field testing, a sample thief of suitable dimensions may be more convenient than a hydrometer cylinder. The liquid level shall be level with the top of the thief.

6.3 Temperature Bath, to control temperature close to the bulk hydrocarbon temperature or to control temperature close to the reference temperature of 15°C or 60°F.

7. Sampling, Test Specimens, and Test Units

7.1 Unless otherwise specified, samples of non-volatile petroleum and petroleum products shall be taken by the procedures described in Practices D4057 (API MPMS Chapter 8.1) and D4177 (API MPMS Chapter 8.2).

7.2 Samples of volatile crude petroleum or petroleum prod- ucts are preferably taken by Practice D4177 (API MPMS Chapter 8.2), using a variable volume (floating piston) sample receiver to minimize any loss of light components which may affect the accuracy of the density measurement.

In the absence of this facility, extreme care shall be taken to minimize these losses, including the transfer of the sample to a chilled container immediately after sampling.

7.3 Sample Mixing—May be necessary to obtain a test portion representative of the bulk sample to be tested, but precautions shall be taken to maintain the integrity of the sample during this operation. Mixing of volatile crude petro- leum or petroleum products containing water or sediments, or both, or the heating of waxy volatile crude petroleum or petroleum products may result in the loss of light components. The following sections (7.3.1-7.3.4) will give some guidance on sample integrity maintenance.

7.3.1 Volatile Crude Petroleum and Petroleum Products Having an RVP Greater than 50 kPa—Mix the sample in its original closed container in order to minimize the loss of light components.

N OTE 1—Mixing volatile samples in open containers will lead to loss of light components and consequently affect the value of the density obtained.

7.3.2 Waxy Crude Petroleum—If the petroleum has an expected pour point above 10°C, or a cloud point or WAT above 15°C, warm the sample to a temperature that is sufficient for ensuring the material is fluid enough to provide adequate mixing without excessively heating the material that would otherwise compromise the integrity of the sample. Samples heated to 9°C above its pour point, or 3°C above its cloud point or WAT have been found to be suitable temperatures to warm samples prior to mixing. Whenever possible, mix the sample in its original closed container in order to minimize the loss of light components.

7.3.3 Waxy Distillate—Warm the sample to a temperature that is sufficient for ensuring the material is fluid enough to provide adequate mixing without excessively heating the material that would otherwise compromise the integrity of the sample. Samples heated to 3°C above its cloud point or WAT have been found to be suitable temperatures to warm samples prior to mixing.

7.3.4 Residual Fuel Oils—Heat the sample to the test temperature prior to mixing (see 9.1.1 and Note 3).

7.4 Additional information on the mixing and handling of liquid samples will be found in Practice D5854 (API MPMS Chapter 8.3).

8. Apparatus Verification or Certification

8.1 Hydrometers and thermometers shall be verified in accordance with the procedures in Annex A1.

9. Procedure

9.1 Effect ofTest Temperature:

9.1.1 The density or API gravity determined by the thermo- hydrometer method is most accurate at or near the reference temperature of 15°C or 60°F. Other temperatures within the range of the enclosed thermometer may be used, if consistent with the type of sample and the necessary limiting conditions shown in Table 3.API MPMS 9.3 pdf download.API MPMS 9.3:2012 pdf free download