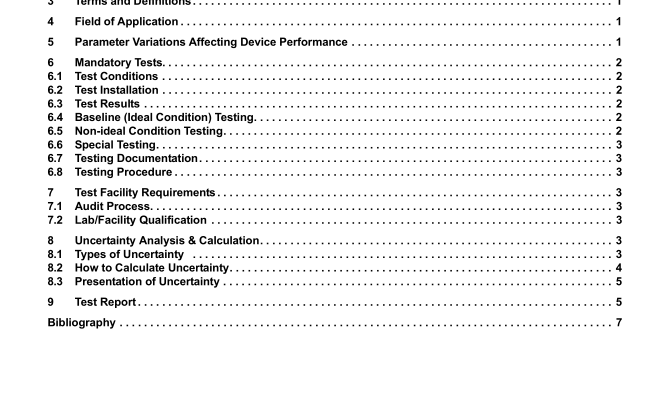

API MPMS 22.1:2015 pdf free download.Manual of Petroleum Measurement Standards Chapter 22.1 General Guidelines for Developing Testing Protocols for Devices Used in the Measurement of Hydrocarbon Fluids

6.6 Special Testing Special tests may be defined where the combined effect of variations in multiple factors may be tested to reduce the cost of performance testing of the device. Whenever possible, tests should be designed to produce results to reflect the influence of one well-defined variable at a time.

6.7 Testing Documentation All data used to calculate the final or intermediate result shall be recorded, attested, and/or certified by the test facility. If tests are performed at a third party facility, results shall be retained for future reference. These test results shall be retained for the period of time defined by the document. If a specific test report is not published in the public domain and is not available for verification of the performance claim, the associated claim will be deemed unverifiable.

6.8 Testing Procedure The document shall describe in detail how the tests are to be conducted or reference other published procedure(s) for similar type tests, if type testing is permitted for the device. 7 Test Facility Requirements

7.1 Audit Process To assure adherence to the testing protocols defined in this chapter, the laboratory or testing facility performing the tests shall provide documentation that the tests are performed in accordance with the standard. This documentation shall be provided at the request of any user of the facility.

The user of the facility can request an audit of the laboratory or the testing facility to ensure the validity of the tests. The depth of the audit is determined by the user of the facility and shall be consistent with relevant national and/or international standards. The user of the facility may require the laboratory or testing facility to be traceable to national or international standards of weights and measures.

The laboratory or testing facility shall provide documentation of how it estimates the uncertainty of its systems and procedures and how that uncertainty is maintained throughout the testing process under this protocol. A user of the facility wanting a detailed analysis of the performance of the lab/facility, may request to review its applicable procedures and processes.

7.2 Lab/Facility Qualification The testing procedure defined in the standard may require a lab/facility to meet minimum performance criteria in order to demonstrate that the facility can successfully perform the test with acceptable precision. This is not an audit of the lab/facility, but may be necessary to ensure that the intent of the testing protocol is being followed. This also allows manufacturers to perform testing at their own facility, provided the facility can meet the qualification requirements of the testing protocol and the requirements of the user. 8 Uncertainty Analysis & Calculation

8.1 Types of Uncertainty

8.1.1 General The testing protocol shall clearly define any specific uncertainty terms and how the value is determined. For example, pressure devices typically have values for linearity, hysteresis, and repeatability, ambient temperature effects, stability, and static pressure effects. If terms such as these are to be used in any section of the testing protocol, the protocol shall establish precise definitions, test procedures, and calculation methodologies for each. The testing protocol should also describe how overall device uncertainty is affected by the various operational effects. In the presentation of uncertainty, the results of each test should be separated.

8.1.2 Test Facility Uncertainty

Each testing protocol shall define a methodology to determine the uncertainty of the parameters applied by the test facility to the device being tested. Such parameters may include flow rate, pressure, temperature, frequency, and electrical values (milliamps, millivolts, Farads, etc.). A test facility may supply a national certification statement to validate the facility uncertainty.

The test facility shall define and state the system uncertainty for the device being tested and if requested by the user of the facility or the user of the device, shall provide the documentation of the method and calculation procedure used to establish the measurement uncertainty of the test. If the test facility does not provide the requested verifiable documentation used to establish and determine the measurement uncertainty of the tests, test results of that facility shall not be accepted in defining the measurement uncertainty of the device.API MPMS 22.1 pdf download.API MPMS 22.1:2015 pdf free download