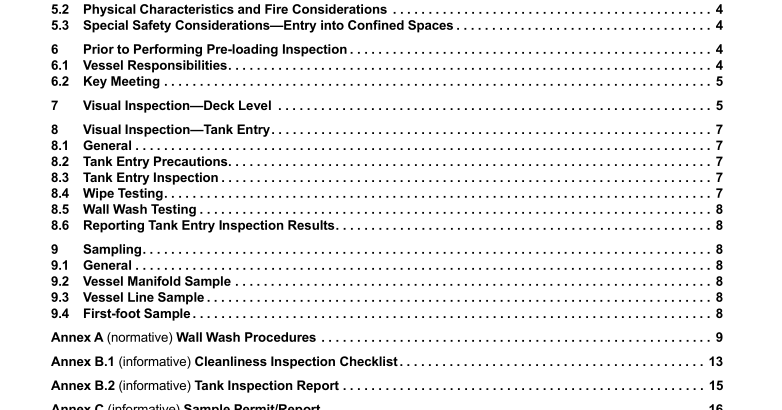

API MPMS 17.8:2016 pdf free download.Manual of Petroleum Measurement Standards Chapter 17.8 Guidelines for Pre-loading Inspection of Marine Vessel Cargo Tanks and Their Cargo-handling Systems

8 Visual Inspection—Tank Entry

8.1 General Tank and cargo-handling system cleanliness testing and inspection procedures should be determined by the parties involved. Below are examples, common in industry, to determine suitable cleanliness. Additional customer requirements may be used to determine cleanliness of tank and cargo-handling system prior to loading. The method agreed by the parties should establish the requirements.

8.2 Tank Entry Precautions Section 5.3 and all safety requirements specified by the relevant documents/regulations shall be followed before entering any vessel tank. A standby person shall be stationed at the tank hatch at all times while personnel are in the tank. At minimum, an entry permit shall contain the information detailed in the sample Confined Space Entry Permit (Table C.1).

8.3 Tank Entry Inspection

Prior to any tank entry inspection, all pipelines leading to the tank should be verified, to the extent possible, to be empty and free of potential contaminants (Annex D). An examination of accessible pipelines, including pump drains and manifolds, should be completed. Removal of any inspection flanges and access plates to facilitate the inspection of the interior of the cargo-handling system shall be performed by the vessel personnel where not in place for energy isolation. Space shall be segregated by blinding or isolating all connecting pipelines and all valves on pipelines serving spaces shall be secured. The tank atmosphere should be tested and permitted for safe entry after any changes in valve settings (Annex C). Heating coils should be either drained or blown, and blinded, or tested for tightness. The following inspection shall be performed and recorded upon tank entry.

— All tank surfaces—including internal pumps, sumps, heating coils, and all pipe surfaces—that can be accessed without staging or equipment should be examined for possible sources of contamination (Annex D).

— Tank coating should be examined for signs of deterioration, such as blistering, flaking, or areas where the metal beneath the coating is visible. Knowledge and experience of the visual inspection and estimation of cargo tank coatings and determination of coating type and condition or integrity (% of total coating in place or % breakdown of the coating in place) may be required to ensure that the tank inspection result meets the requirements and expectation of the parties for whom the inspection is being performed. Coating condition should be detailed in the inspection documentation and may be included in the Cleanliness Inspection Checklist (Annex B.1).

— All internal piping, pump housing, etc. shall be opened for inspection, where appropriate. Caution—To avoid possible release of hazardous materials, blisters in the tank coating should be investigated with caution. Piles of rust or debris on the tank floor should be left undisturbed and noted. Removal of such scale, rust, or detached tank coating should be done by vessel personnel.

NOTE Prior to loading some chemical cargoes, it is recommended to pop/blow the lines with dry air, carbon dioxide, nitrogen, or other acceptable gases from manifold to tank to verify that the lines associated with the cargo-handling system are liquid free. This may not be allowed at all installations.

8.4 Wipe Testing A wipe test may be performed on any tank surface.

8.5 Wall Wash Testing

If wall wash testing is required, follow the wall wash testing procedures in Annex A.

8.6 Reporting Tank Entry Inspection Results

After completing inspection, inspection personnel shall report results to the appropriate parties.

When cargo-handling system inspection procedures have been completed, inspection personnel shall prepare written documentation of inspection results, which may be included on a Cleanliness Inspection Checklist(s) and Tank Inspection Report(s). Vessel personnel shall confirm completion of work. The time of acceptance or rejection with reasons of the tank shall be recorded. (See example in Annex B.2.)API MPMS 17.8 pdf download.API MPMS 17.8:2016 pdf free download