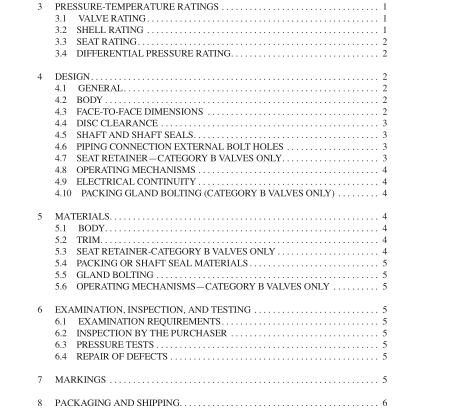

API 609:2004 pdf free download.Butterfly Valves: Double Flanged, Lug- and Wafer-Type

Note 1: When valve body liners, slceves, or O-ring seals act as flange-sealing surfaces, separate gaskets should not be used unless specifially recommended by the manufacturer.

Note 2: Valves with liners that extend to the gasket seating surfaces should be bolted up with the disc in the partially open position.

4.3.2 Face-to-face dimensions for double flanged valves are listed in Table 2-B for long patterm valves, or Table 2-C for short pattern valves.

4.3.3 Body contact faces of cast iron, ductile iron, and cast copper alloy valves that require separate gaskets shall be fin- ished as specified in MSS SP-6.

4.3.4 Body contact faces of steel or alloy valves that require separate gaskets shall be finished as specified in ASME B165.

4.4 DISC CLEARANCE The manufacturer shall design the valve disc to provide suit- able clearance, in accordance with the ASME class rating for the valve, the inside diameter of the connecting pipe or flange, and the criteria covered in the appendix to this standard. Note: For lug and wafertype valves and some double flanged designs, the disc will project beyond the body faces when the disc is turned. The purchaser should review the design of the piping to ensure that there will be no interference between the dise and adja- cent components such as the pipe lining. strainers, check valves, and other valves, During valve intallation, the mating flanges shall be aligned before final tightening of the fange bolts to ensure proper valve operation and the seating of any seals and gaskets.

4.5 SHAFT AND SHAFT SEALS

4.5.1 The shaft to disc connection and all parts of the shaft within the pressure boundary shall, under torsional load, exceed the strength of the shaft that lies outside the pressure boundary by more than 10%。The determination of shaft strength shall be by calculation or testing.

4.5.2 The shaft and/or shaft retention shall be designed so that, if failure of the shaft to disc conection or of the shaft occurs, no portion of the shaft can be ejected from the valve as a result of intemal pressure. ‘The design shall not rely on actuation components (e.go, gear operators, actuators, levers, etc.) to prevent shaft ejection.

4.5.3 The shafl-to-dic connection shall be designed to pre- vent loosening due to vibration.

4.5.4 For Category B valves, the shaft shall have a surface finish of 32 microinches (0.80 micrometers) Ra or smoother in the area in contact with the packing, and the stuffing box shall have a surface finish of 125 microinches (3.2 microme- ters) Ra or smoother. API 609 pdf download.API 609:2004 pdf free download