API MPMS 2.2F:2004 pdf free download.Petroleum and Liquid Petroleum Products—Calibration of Horizontal Cylindrical Tanks Part 2: Internal Electro-optical Distance-ranging Method ANSI/API MPMS Chapter 2.2F First Edition, April 2004 ISO 12917-2, Petroleum and liquid petroleum Products—Calibration of horizontal cylindrical tanks, Part 2: Internal Electro-optical Distance-ranging Method

4 Precautions The general and safety precautions given in ISO 7507-1 shall apply to this part of ISO 12917. In addition, the laser beam fitted to the EODR instrument shall be operated in conformity with IEC 60825-1. The hazards, if any, in the area in which the calibration is to be carried out shall be assessed in accordance with IEC 60079-10. The equipment to be used in the calibration shall be certified as being safe for use in the area of operation.

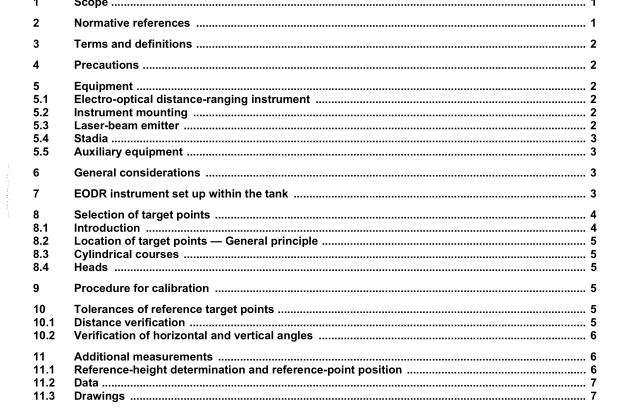

5 Equipment

5.1 Electro-optical distance-ranging instrument

5.1.1 The angle-measuring part of the instrument shall have an angular graduation and resolution equal to or better than 0,002 gon. This part of the instrument shall have a repeatability equal to or better than ± 0,005 gon.

5.1.2 The distance-measuring part of the instrument, used for direct determination of distances, shall have a graduation and resolution equal to or better than ± 1 mm. This part of the instrument shall have a repeatability equal to or better than ± 2 mm.

5.2 Instrument mounting A tripod which is firm and stable. The legs of the tripod may be held firm, and steadied, by suitable devices such as magnetic bearers.

5.3 Laser-beam emitter A low-power laser beam complying with IEC 60825-1, which is either an integral part of the EODR instrument or a separate device. If the laser beam emitter is a separate device, it may be fitted with a fibre-optic light transmitter system and a theodolite telescope eyepiece connection, by which the laser beam may be transmitted through a theodolite, or such that it may be fitted to a theodolite with its axis co-incident to the axis of the theodolite. NOTE The laser-beam emitter is used to position target points on the tank shell.

5.4 Stadia A rigid bar, usually 2 m long, such that the graduated length between the two stadia marks remains constant to within ± 0,02 mm.

5.5 Auxiliary equipment Auxiliary equipment includes a) magnets or other equipment to steady the unit, and b) lighting within the tank, if required. 6 General considerations 6.1 The EODR instrument shall be maintained so that the values of their measurement specifications do not exceed the values given in this part of ISO 12917.

6.2 Tanks shall only be calibrated after they have been filled at least once with a liquid of density equal to or greater than that of the liquid which they will hold when in use, and at a pressure greater than the pressure at which they will operate when in service. NOTE The hydrostatic or pressure test applied to new tanks will satisfy this requirement in most cases.

6.3 Calibration shall be carried out without interruption.

6.4 The EODR instrument shall be verified prior to calibration. The accuracy of the distance-measuring unit as well as the angle-measuring unit shall be verified using the procedures recommended by the manufacturer (e.g. a stadia or reference laser may be used for distance measurement). The procedures given in ISO 7507-4:1995, annex A should be used for the verification of field equipment.

6.5 The tank shall be free from vibration and airborne dust particles. NOTE The floor of the tank should be as free as possible from debris, dust and loose scale.

6.6 Lighting, when required, shall be placed within the tank so as not to interfere with the operation of the EODR instrument. 7 EODR instrument set up within the tank

7.1 The number and locations of the instrument stations shall be determined in order not to exceed incidence-angle limitations of equipment (see normative annex A). A typical minimum angle may be 10 gon. If more than one station is necessary, survey traverse techniques should be used to move from one station to the other and the procedure in this subclause repeated.

7.2 The instrument shall be set up with care, particularly in the horizontal and vertical axes and according to the procedure and instructions given by the manufacturer.

7.3 The instrument shall be set up so as to be stable and free from external vibrations. If necessary, the tank shell, in the vicinity of the instrument, shall be made firm and steady by placing heavy weights in the area. The legs of the tripod on which the instrument is mounted may be steadied using suitable devices, such as magnetic bearers, to prevent slippage on the tank bottom.API MPMS 2.2F pdf download.API MPMS 2.2F:2004 pdf free download