API TR 11L6:2008 pdf free download.Technical Report on Electric Motor Prime Mover for Beam Pumping Unit Service

4.1.13 Bearing Life Bearings shall be selected to provide L-10 rating life of 26,280 hours minimum (3 years continuous) per ABMA-9 or ABMA-11 as applicable. Calculations shall be based on external loads calculated for NEMA bolted application limits in accordance with NEMA MG 1 and internal loads defined by the manufacturer. Regressable bearings shall be provided on frame sizes above 286T.

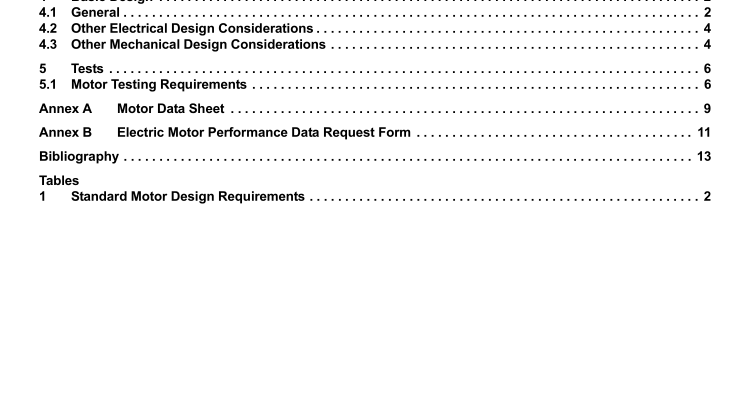

4.2 Other Electrical Design Considerations 4.2.1 Power Supply Variations

4.2.1.1 Motors shall operate on a continuous basis at rated load with variation in the voltage or the frequency not exceeding the following conditions: a) ± 10 % of rated voltage, with rated frequency; b) ± 5 % of rated frequency, with rated voltage; and c) combination of voltage and frequency variation of 10 % (sum of absolute values) of the rated values, provided that the frequency variation does not exceed ± 5 % of rated frequency.

4.2.1.2 Motors shall operate on a continuous basis at rated load and frequency when the voltage unbalance at the motor terminals is less than or equal to 1 % as calculated according to NEMA MG 1.

4.2.1.3 When elevation or ambient temperatures other than specified in 4.1.2 are noted on the data sheet, the motor shall be derated in accordance with NEMA MG 1.

4.2.2 All motors shall have nonhygroscopic insulation systems including loads and connections. Internal winding encapsulation may be specified. Coil ends shall be braced to prevent insulation cracking and fatigue from movement due to starting, operating under cyclic load conditions, and vibrations inherent to a beam pumping system.

4.2.3 The motor insulation system shall be protected against the severe conditions listed in 4.1.2. As minimum the insulation system must pass the salt spray test as specified in ASTM B117.

4.2.4 The motor leads in the motor terminal box shall be constructed of copper motor lead wire and be permanently identified.

4.3 Other Mechanical Design Considerations

4.3.1 Bearings and Lubrication

4.3.1.1 Regressable type bearings should be regressable without any disassembly, and shall contain a reservoir equipped with an outlet for elimination of purged grease. Inlet and outlet openings shall have removable plugs.

4.3.1.2 Regressable bearings should be supplied with as grease compatible with operating conditions specified in 4.1.2. The manufacturers preferred type of grease shall be stated in the maintenance and operating instructions provided with the motor.

4.3.1.3 Temperature rise of the bearing shall not exceed 60 °C at rated load under belted conditions.

4.3.2 Rotors and Rotor Cage Rotor cage construction shall be of copper, aluminum, magnesium or their respective alloys. Rotors shall have a permanent corrosion protective coating. The shaft extension shall be protected against corrosion for shipment and extended storage by a removable protective coating. 4.3.3 Enclosures and Frames 4.3.3.1 Motors with shipping weights over 30 lb shall have lifting lug(s), eye bolt(s), or other suitable means on the frame for lifting.

4.3.3.2 Alignment dowels, rabbet fits or similar construction shall be provided to facilitate correct reassembly of frame components, end bells or plates, bearing housing mounting plates, and bearing housings.

4.3.3.3 On TEFC motors, non-threaded, 3 / 16 -in. diameter hole(s) shall be provided at the low point(s) of the motor enclosure to allow for drainage of condensation. Holes larger than 3 / 16 -in. diameter must be provided with threaded plugs or automatic drainage fittings

. 4.3.4 Paint Requirements

4.3.4.1 Manufacturer’s standard paint color shall be as specified on the Motor Data Sheet (see Annex A).

4.3.5 Accessories

4.3.5.1 Motor nameplates, attachment hardware and connection diagram shall be stainless steel and shall be located on the same side of the motor above the terminal box. Nameplates with permanent markings shall contain the following data in accordance with NEC 430-7(a), (b) and NEMA MG 1.37-40, and this technical report:

— manufacturer’s name;

— rated volts and full load amps;

— motors for dual voltage use slash between voltages and amperes;

— rated frequency and number of phases;API TR 11L6 pdf download.API TR 11L6:2008 pdf free download