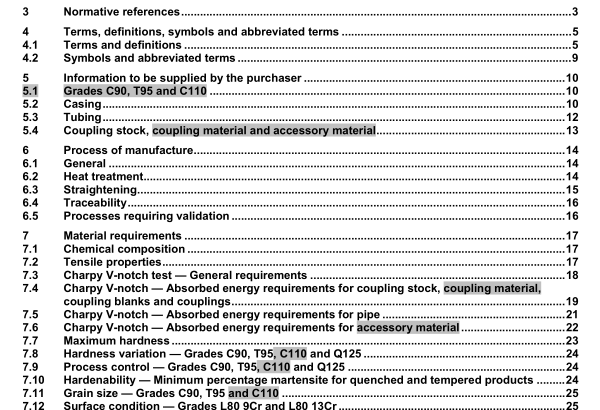

API SPEC 5CT:2016 pdf free download.Specification for Casing and Tubing

7.2.3 Yield strength

The yield strength shall be the tensile stress required to produce the elongation under load specified in Table C.5 or Table E.5 as determined by an extensometer. Additional requirements for PSL-3 products are specified in Annex H.

7.2.4 Statistical tensile testing – Grades C90, T95 and C110 By agreement between purchaser and manufacturer the supplementary requirements for statistical tensile testing of Grades C90, T95 and C110 in A.12 (SR38) shall apply.

7.3 Charpy V-notch test — General requirements

7.3.1 Evaluation of test results

A test shall consist of a set of three specimens taken from one location from a single tubular product length. The average value of the three impact specimens shall equal or exceed the absorbed energy requirement specified in 7.4, 7.5 and 7.6. In addition, not more than one impact specimen shall exhibit an absorbed energy below the absorbed energy requirement, and in no case shall an individual impact specimen exhibit an absorbed energy below two-thirds of the absorbed energy requirement.

For Grade C110 either: a) the minimum shear area shall be 75 %, in accordance with ASTM E23 or b) the manufacturer may use a documented procedure (taking into account, as a minimum, variations in chemical composition, diameter and wall thickness) together with the impact test results to demonstrate that the upper shelf behaviour is achieved. If the minimum shear area is less than 75 % or if the requirements of b) are not met, then either the material shall be rejected or a transition curve shall be made to demonstrate that the product is on the upper shelf at the specified test temperature (either the standard test temperature or a reduced test temperature specified by the purchaser). Additional requirements for PSL-2 and PSL-3 products are specified in Annex H.

7.3.2 Critical thickness

The absorbed energy requirements are based on the critical thickness. The critical thickness for couplings with API threads is the thickness at the root of the thread at the middle of the coupling, based on the specified coupling diameter and the specified thread dimensions. The critical thickness for all couplings with API threads is provided in Table C.7 or Table E. 7. For pipe, the critical thickness is the specified wall thickness. For other applications, the critical thickness shall be determined as specified in 7.6.6. For coupling stock, coupling materials and accessory materials where the critical thickness is not specified in the purchaser agreement, the critical thickness shall be the specified wall thickness.

7.3.3 Specimen size and orientation

When the use of full-size (10 mm × 10 mm) transverse test specimens is not possible, the largest possible subsize transverse test specimen listed in Table C.8 or Table E.8 shall be used. When it is not possible (or allowed in accordance with 7.3.6) to test using any of these transverse test specimens, the largest possible longitudinal test specimen listed in Table C.8 or Table E.8 shall be used. When testing EW pipe using a transverse test specimen, the weld line shall be positioned at the notch in the Charpy test specimen.

When the outside diameter or wall thickness precludes the machining of longitudinal impact test specimens ½-size or larger, the product need not be tested; however, the manufacturer shall use a chemical composition and processing that is documented and demonstrated to result in impact-energy absorption which meets or exceeds the minimum specified requirement.

7.3.4 Hierarchy of test specimens

The hierarchy of test specimen orientation and size is specified in Table C.9 or Table E.9.

7.3.5 Alternative size impact test specimens At the manufacturer’s option, impact test specimens of an alternative size, listed in Table C.8 or Table E.8, may be used in lieu of the minimum size specified in Tables C.10 to C.15, C.20, C.21 and Tables E.10 to E.15, E.20 and E.21. However, the alternative test specimen selected shall be higher on the hierarchy table (Table C.9 or Table E.9) than the specified size, and the absorbed energy requirement shall be adjusted consistent with the orientation and size of the impact specimen.API SPEC 5CT pdf download.API SPEC 5CT:2016 pdf free download