API RP 554-3:2021 pdf free download.Process Control Systems— Project Execution and Process Control System Ownership

The planning process for any of these types of automation projects consists of:

— identifcation of major portions of the work to be performed;

— quantifcation of the numbers and types of equipment involved; and

— the schedule for engineering and installation.

This process also should provide time and resources for activities that are not necessarily equipment-oriented, such as application development, safety protective system identifcation and design, advanced control or complex applications, system security requirements, etc.

The amount of information necessary for scope defnition and planning of these projects will vary with the type of project and the phase of the planning for the overall project. One often neglected aspect of instrumentation and control projects is modifcations that are required in areas outside of the immediate area of a plant being constructed or modifed.

These scope items often deal with PCS infrastructure, power distribution, utilities, feed, intermediate and product distribution, tankage, and similar areas. These areas are often the most difcult to engineer because they tend to be geographically scattered, may interface to diferent existing control systems, existing systems may be poorly documented, and infrastructure may not be adequate to support the new work without upgrade.

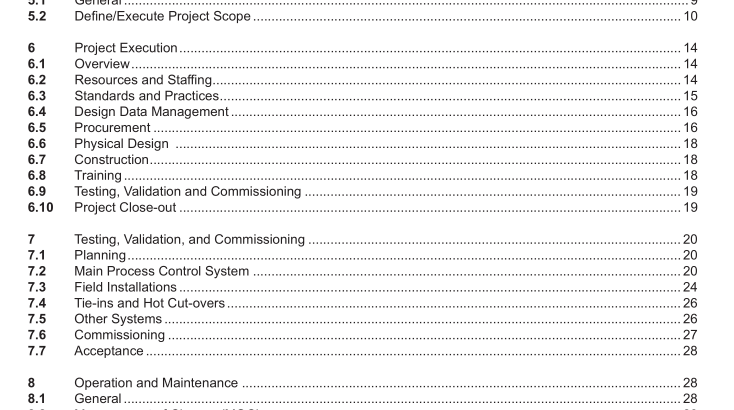

5.2 Defne/Execute Project Scope During the initial project phases, the PCS functional specifcation should have been developed and used as the basis for preliminary estimates and for further scope development for project defnition and execution. The defne/execute project scope development process should address hardware and software selection as well as more detailed analysis of the project execution plan and schedule. The following discussions highlight several of the signifcant items that should be addressed during these scope development activities.

5.2.1 Project Characteristics Scope and planning activities should consider the type of project involved and the limitations that may be placed upon schedule and execution of work.

— Projects that involve new installations on new units are the most straightforward to plan. Completion of design specifcations and drawings, delivery of material, installation, loop check, and commissioning follow well- understood practices and can generally be scheduled to maximize efciency.

— Projects that involve modifcations to existing facilities can be much more complex to schedule and execute. The scope and planning process should recognize constraints that working with an ongoing operation and infrastructure place upon a project.

— Projects that are upgrades of existing PCSs involve relatively little equipment compared with process modifcations, but usually have a much higher engineering content as a percentage of total budget. These projects also usually involve hot cut-over of the PCS, which shall be carefully planned, scheduled, and executed. Installation and commissioning schedules will often be governed by expected unit turnarounds. Installation and commissioning time may be quite limited and may be afected by other turnaround activities. Scheduling of work during a turnaround generally has to be meticulous and be coordinated with other general maintenance activities. The turnaround schedule may require that the amount of preinstallation, pretesting and precommissioning be maximized. Work done while a unit is in operation will not be as efcient and will have to be carefully executed, and special permitting and work rules may be necessary. In some cases, on-stream transfers of control functions may be required.

This will require careful planning and coordination with operations and maintenance personnel to safely isolate systems and to test and commission the modifcations, and usually requires that step-by-step isolation, tie-in, and commissioning procedures be prepared.

5.2.2 Process Control System Life Cycle Table 1 summarizes a typical project life cycle and identifes major inputs and outputs associated with each step. All PCS scope and execution decisions should be made with this life cycle clearly in mind.

All components shall be selected to be consistent with the overall business goals of the projects and shall provide the reliability and maintainability necessary to meet those goals. Many times it may appear that simplifcation or scope reduction would beneft a project, but any proposals to do so should be carefully examined against the long-term business aspects. API RP 554-3 pdf download.API RP 554-3:2021 pdf free download