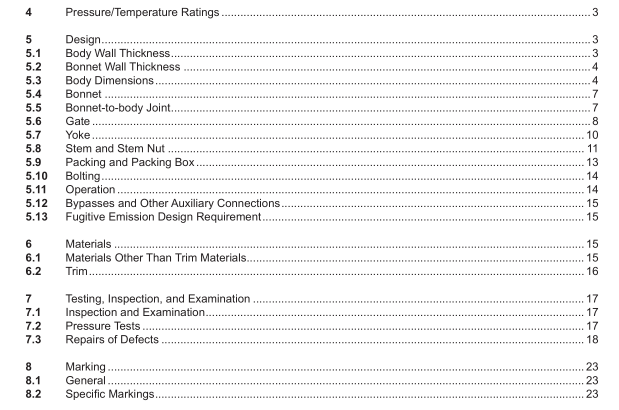

API St 600:2021 pdf free download.Steel Gate Valves—Flanged and Butt-welding Ends, Bolted Bonnets

5.8.8 The stem shall include a conical or spherical raised surface that seats against the bonnet backseat when the gate is at its full open position. A stem-bonnet backseat is a requirement of this standard and, as such, is not meant to imply a manufacturer’s recommendation of its use for the purpose of adding or replacing packing while the valve is under pressure.

5.8.9 The stem nut design shall allow for the removal of the handwheel while keeping the stem (and disc) in a fxed position.

5.8.10 The stem-nut-to-handwheel attachment shall be through a hexagonal interface, a round interface having a keyway, or another means of equivalent strength.

5.8.11 When the stem nut is retained in the yoke by means of a threaded bushing, the bushing shall be secured in place using either a lock weld or a positive mechanical lock. Locking by simple metal upsetting, such as peening or staking, is not permitted.

5.8.12 The closed-position stem thread projection beyond the stem nut, on a new manual handwheel-operated valve, shall be based on the minimum wear travel values listed in Table 3. The minimum distance shall be equal to the manufacturer’s specifed wear travel and the maximum as indicated in Table 3.

5.8.13 Valves DN ≥ 150 (NPS ≥ 6) with pressure class ≥ 600 shall be furnished with stem nuts having ball or roller bearings.

5.9 Packing and Packing Box

5.9.1 The packing may be square, rectangular, or trapezoidal in cross-section. The nominal radial width of the packing, w, shall be in accordance with Table 5 and Table 6 for respective units (metric/U.S. Customary).

5.9.2 The nominal depth of the packing box shall accommodate a minimum of fve uncompressed rings of packing. Unless otherwise specifed by the purchaser, the packing box surface area in contact with the packing material shall have a surface fnish, Ra, of 4.5 µm (175 µin.) or smoother.

5.9.3 The maximum bore (inside diameter) of the packing box shall be the sum of the nominal valve stem diameter plus twice the nominal packing width plus a clearance factor, y, i.e., equal to d n + 2w + y. See Table 5 and Table 6 for the required values.

5.9.4 A gland and a separate gland fange shall be provided for packing compression. The gland fange shall have two holes to receive the gland bolting. Slots for gland fange bolts shall not be used. The gland and gland fange shall be self-aligning.

The gland shall have a shoulder at its outer edge so as to prevent complete entry of the gland into the packing box. Packing gland assembly (including gland fange, follower, bolting, and anchoring pins) shall have adequate strength to transmit load without permanent deformation under required packing load.

5.9.5 A lantern ring shall be provided only if so specifed by the purchaser. To accommodate the lantern ring, the packing box depth shall be at least equivalent to that of a minimum of three uncompressed rings of packing above the lantern ring and three uncompressed rings of packing below the lantern ring plus the length of the lantern ring. 5.9.6 The clearance between the packing box bore (inside diameter) and the outside diameter of the gland (see Figure C.1) shall be nominally less than the diametrical clearance between the inside diameter of the gland and the stem diameter.

5.9.7 See 5.13 for additional packing requirements.

5.10 Bolting

5.10.1 Bolting shall be standard inch series bolting, except if the purchaser specifes metric series bolting. Bolting for the bonnet-to-body joint shall be continuously threaded stud bolts with heavy, semi-fnished hexagon nuts that are in accordance with ASME B18.2.2 or ASME B18.2.6M.

5.10.2 Yoke-to-bonnet bolting shall be either continuously threaded stud bolts or headed bolts with hexagon nuts.

5.10.3 Gland bolts shall be hinged eyebolts, headed bolts, stud bolts, or studs. Hexagon nuts shall be used.API St 600 pdf download.API St 600:2021 pdf free download