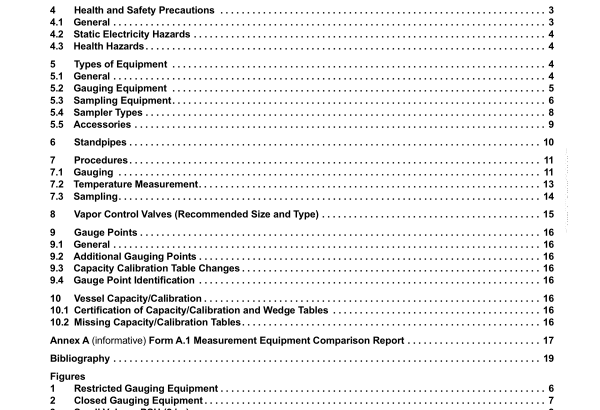

API MPMS 17.11:2016 pdf free download.Manual of Petroleum Measurement Standards Chapter 17.11 Measurement and Sampling of Cargoes On Board Tank Vessels Using Closed and Restricted Equipment El Hydrocarbon Management HM 52

5.2 Gauging Equipment

5.2.1 Restricted Gauging Restricted equipment is designed to substantially reduce or minimize the amount of vapor release that would occur during open gauging or sampling, but may still allow some quantity of vapor to escape because the equipment is not completely gas tight.

This vapor release will be increased if the cargo tank is blanketed with either inert gas or nitrogen under positive pressure. Portable measurement units (PMUs) are designed to measure bulk liquid levels, water levels, and/or temperatures of a cargo in a tank.

The units may be designed to perform one, two, or all three of these functions. Multifunction units are sometimes referred to as ullage, temperature, and interface (UTIs). PMUs use an electronic sensing device integrated into a measuring tape.

The PMU comprises an electronic head and tape fitted to an extension tube. This tube houses the tape bob/sensor probe when it is withdrawn from the tank. The PMU is fitted with a means to provide a tight seal onto the VCV. However, the tape is open and a simple wiper seal reduces vapor loss as the tape is raised and lowered. The extension tube fills with vapor when the VCV is opened, and this vapor escapes when the PMU is removed from the VCV after completion of the measurement operation. Generally, PMUs and VCVs made by the same manufacturer are designed to be used together. However, equipment made by different manufactures may be used together with appropriate adapters that either do not require measurement correction or have a known fixed correction.

The manufacturer’s instructions should be carefully reviewed and followed. In addition, the manufacturer’s maintenance schedule should be followed and a log kept of all maintenance and verifications performed on each device. PMUs shall be verified and records kept in accordance with API MPMS Chapter 3 and API MPMS Chapter 7. When measurement equipment is first put into service, it shall be carefully inspected for any signs of damage or construction flaws. The measurement tapes of all PMUs should be compared against a certified master tape to be certain the linear markings on the tape are correct and in accordance with API MPMS Chapter 3.1 A. All equipment and fittings should be checked for proper size, operation, seating, and any signs of wear before each use. (See Figure 1 for an example of restricted gauging equipment.)

5.2.2 Closed Gauging Closed gauging equipment does not permit the release of any tank contents to the atmosphere during gauging. Equipment is similar to that described above for restricted gauging except that the tape housing is completely enclosed and gas tight, and provision should be made for purging the contents of the tape housing and tube before it is removed from the VCV. (See Figure 2 for an example of closed gauging equipment.)

5.3 Sampling Equipment

5.3.1 Restricted Sampling Portable sampling units (PSUs) designed to obtain samples under restricted conditions operate via VCVs fitted to the vessel and are very similar to the restricted gauging PMUs described in 5.2.1 except that the electronic head, sensor, and tape are replaced with a simple tape system. (See Figures 3 and 4 for examples of portable sampling units.) Samplers (sample containers) of various types can be placed inside the extension tube, lowered to the desired level in the tank, and then retrieved. The VCV can then be closed and the sampler removed with a limited release of vapor.

5.3.2 Closed Sampling Closed system equipment is designed to be completely gas tight during sampling to prevent release of vapor to the atmosphere. Similar to the closed system PMUs, the tape housing is hermetically sealed and the design should allow sample transfer to secondary (transportation) receivers with minimal vapor release.API MPMS 17.11 pdf download.API MPMS 17.11:2016 pdf free download