API MPMS 7.1:2017 pdf free download.Manual of Petroleum Measurement Standards, Chapter 7.1 Temperature Determination— Liquid-in-Glass Thermometers

6 Equipment and Design Requirements

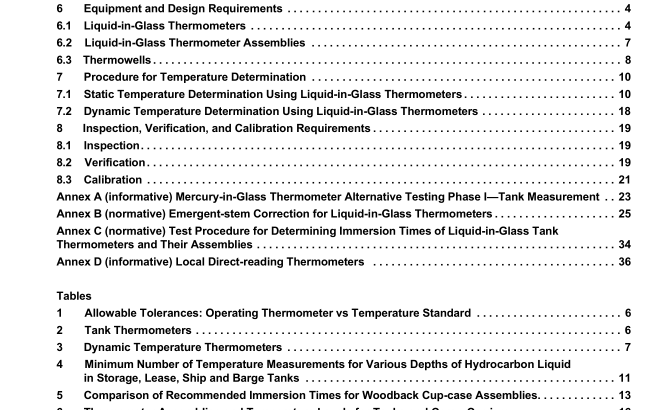

6.1 Liquid-in-Glass Thermometers

6.1.1 General Information Due to the identified hazards associated with mercury-in-glass thermometers (MIGTs), its use is being phased out. API, in collaboration with the U.S. Environmental Protection Agency, conducted a comparison study of MIGTs to other liquid-in-glass and digital thermometers in order to provide a comparison of the accuracies of each type of device. The testing indicated that alternative liquid-in-glass thermometers meeting the requirements in ASTM E2251 can be substituted for MIGTs. Annex A provides additional details of the testing that was conducted.

6.1.1.1 Thermometer Specifications Glass thermometers include total-immersion thermometers and partial-immersion thermometers (see Figure 1 and refer to ASTM E344). These thermometers should conform to the specifications in ASTM E1 or E2251 for thermometers, or to the National Institute of Standards and Technology (NIST) specifications. Calibration does not have to be done by a national metrology institute (NMI) (e.g. NIST in the United States), but the certified instruments used for the calibration shall be traceable to a NMI. ASTM thermometers are designed to be either total immersion (thermometer immersed in the medium to be measured to the top of the thermometer liquid column) or partial immersion (thermometer in the medium to be measured to a specific depth marked on the thermometer).

Tank thermometers used in conjunction with a cup-case assembly are total-immersion thermometers that are completely immersed into the tank but only a portion of the thermometer is immersed in the cup when read. Testing has shown that the accuracy of the reading is not affected when read quickly after being raised out of the tank. Operating thermometers that are used in static or dynamic measurement shall be compared on a regular basis (see Section 8) to a temperature standard. The recommended allowable tolerances between the operating thermometer and the NMI traceable thermometer are shown in Table 1, and are provided as a reference for limits considered acceptable for static and dynamic temperature determinations in custody transfer measurement of petroleum and petroleum products.

6.1.1.2 Permanent Glass Thermometers Securely mount permanently installed glass thermometers in a thermowell and protect from breakage by the use of a housing. They shall have the same high resolution scale graduation interval and tolerance as glass test thermometers. These thermometers shall be calibrated and checked using test thermometers as described in Section 8.

6.1.1.3 Tank Thermometers Tank thermometers shall be of the total immersion type and shall be made in accordance with the specifications in ASTM E1 or E2251. Each thermometer shall be the liquid-in-glass type with nitrogen or another suitable inert gas filling the space above the liquid column, and with graduation marks permanently etched on its glass stem. Angle- stem thermometers may use a separate graduated scale, as discussed in 6.2.3. The thermometers listed in Table 2 shall be used.

6.1.1.4 Dynamic Measurement Thermometers ASTM E1 glass thermometers that meet the discrimination requirements for dynamic measurement are shown in Table 3. These glass thermometers are designed and calibrated for immersion to the scale level corresponding to the temperature of the liquid. These thermometers normally have scale graduations of either 0.1 C or 0.5 C (0.2 F or 1.0 F) and a tolerance of either 0.1 C or 0.25 C (0.2 F or 0.5 F). When used in a manner other than total immersion, errors may occur due to the differential expansion of the glass and liquid column in the stem. When used for meter prover calibration and for checking and calibrating temperature devices used for meter proving, potential scale errors and stem corrections shall be analyzed, and corrections should be applied. Normally, stem corrections are not significant unless the difference between the average stem temperature and liquid temperature is greater than 8 C (15 F). Consider the stem correction on a case-by-case basis. Annex B provides information about the methods for stem correction.API MPMS 7.1 pdf download.API MPMS 7.1:2017 pdf free download