API TR 17TR6:2012 pdf free download.Attributes of Production Chemicals in Subsea Production Systems

5.2 Parameter Verification

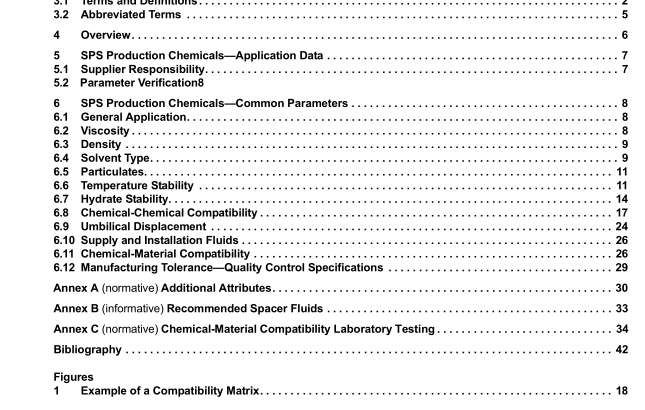

The range of attributes addressed in this document relate to the installation, commissioning and operation of the SPS and is divided into those for which measurement shall be taken and reconciled against the SPS operational envelope and those for which acceptance criteria can be provided.

The attributes and related parameters addressed in clause 6 constitute the minimum requirement and shall be verified for every instance of production chemical supply. Annex A sets out requirements relating to other attributes that may be relevant to some SPSs. For SPSs and associated production chemicals to which such attributes apply, the requirements of this annex shall be met.

6 SPS Production Chemicals—Common Parameters

6.1 General Application The verification data provided in relation to a production chemical submitted for introduction to an SPS, shall include the parameters identified in 6.2 through 6.13, as a minimum.

6.2 Viscosity

6.2.1 Requirement Viscosity measurements at a range of temperature/pressure combinations corresponding to host facility, subsea and well conditions, shall be taken to determine whether a production chemical can be injected at the required volumetric rate. The SPS operational envelope shall define the range of conditions selected for measurement of viscosity.

NOTE 1 Viscosity data are essential to determine whether or not a production chemical injection system can deliver at the required volumetric rate, or whether a production chemical has a viscosity that will permit its use in an existing injection system. The viscosity of a production chemical will vary as a function of temperature and pressure.

NOTE 2 The viscosity of hydrocarbon based production chemicals tends to exhibit the greatest pressure dependence. However, water/glycol based production chemicals can also exhibit a significant dependence. In addition, some production chemicals exhibit non-Newtonian behavior where viscosity varies as a function of shear rate.

6.2.2 Procedure

6.2.2.1 Measurement Viscosity measurements shall be made using a method of the chemical providers own choosing, in accordance with a published standard. Reporting of the results of viscosity measurement shall always include identification of the method employed and corresponding standard.

Should the SPS Operator not be satisfied with the results reported, the viscosity of the chemical shall be checked using one of the following methods:

— capillary viscometer;

— flow cup;

— rotational viscometer;

— rolling ball viscometer; and

— drawing ball viscometer.

6.2.2.2 Measurement at Elevated Temperature Related viscosity measurement at elevated pressure shall be made using a method that is based on the principles of an atmospheric pressure measurement standard. Reporting of the results of viscosity measurement shall always include identification of the method employed and corresponding standard that is the basis of the method.

NOTE 1 OECD Guideline for testing of chemicals 114 “Viscosity of liquids” provides extensive details of available standards.

NOTE 2 Elevated pressures: Standards specifically for elevated pressure are not published. However, general specifications presented in standards can be applicable and should be considered when making measurements.

NOTE 3 It is recommended that at least two determinations should be made at each set of conditions.

6.2.3 Interpretation of Results The measured viscosities shall be reconciled with the requirements of the SPS operational envelope to demonstrate that any specific production chemical can be injected at the required volumetric rate(s).

6.3 Density

6.3.1 Requirement Density data are essential to the undertaking of an accurate hydraulic analysis of the production chemical injection system. Density measurement at a range of temperature/pressure combinations corresponding to the SPS operational envelope, shall be taken to determine whether a production chemical can be injected at the required volumetric rate.

6.3.2 Procedure Density measurements shall be made using a method specified in a published standard and reference to the standard method used shall always be included in a report of results. Where other specific standards are not selected for use and reference, either IP160 or ASTM D1298 shall be used as the default standard for the measurement of production chemical density.

6.3.3 Interpretation of Results The measured densities shall be reconciled with the SPS operational envelope to demonstrate that any specific production chemical can be injected at the required volumetric rate(s).API TR 17TR6 pdf download.API TR 17TR6:2012 pdf free download