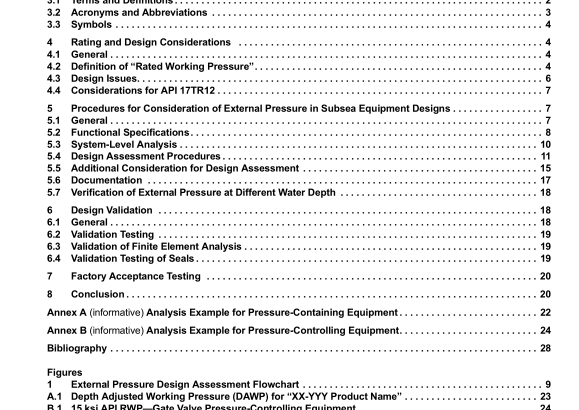

API TR 17TR12:2015 pdf free download.Consideration of External Pressure in the Design and Pressure Rating of Subsea Equipment

4 Rating and Design Considerations

4.1 General In the context of this technical report, there are several considerations that need to be discussed in order to provide background information as related to the consideration of external pressure in the design of subsea equipment.

4.2 Definition of “Rated Working Pressure”

There can be differing definitions for the term “rated working pressure” (RWP) when evaluating the effects of internal and external pressures in the design of subsea equipment. This technical report provides clarification of rated working pressure for subsea equipment which is subjected to external hydrostatic pressure from the in situ environment. Relative to API 6A, API 16A and API 17D oilfield equipment, the term “rated working pressure” is currently defined as “the maximum internal pressure that the equipment is designed to contain and/or control” and usually interpreted as absolute internal pressure minus 14.7 psia. This has been commonly simplified to the “absolute internal pressure” of the fluid contained within the equipment, measured in “psia” (psi absolute). However, wording between API 6A and API 17D are inconsistent.

Confusion can arise when the terms “absolute” and “gage” or “gauge” pressure are used in subsea applications. Gauge pressure is the pressure relative to the local atmospheric or ambient hydrostatic pressure. At sea level, the absolute pressure in air is 14.7 psia, and the gage pressure is 0 psig. These terms could also be adopted for subsea, but the equipment designer needs to then be careful with the nomenclature and application. Piezo-electric digital pressure transducers provide an absolute pressure reading.

Analog pressure gages are typically compensated, and therefore, provides a pressure reading relative to local hydrostatic pressure. For subsea pipelines in the oil and gas industry, the term “pressure” is intended to mean the “differential pressure” acting on the pressure-containing equipment (absolute internal pressure minus absolute external pressure), measured in units of “psi” (see API 1111 and BSEE NTL No. 2009-G28). It is important that guidelines, industry standards or RPs, and design documents be explicit wherever practical about definitions of the word “pressure”. Wherever “pressure” is described, the location needs to be defined and whether the pressure is internal pressure, external pressure, or differential pressure.

API 1111 is consistent in this terminology, and is based on use of differential pressure. However, it is recognized that some regulations at present do not use the term “differential” pressure but pipeline design codes do. For subsea hydraulic control systems and related components, rated working pressure (RWP) is typically considered to be the “differential pressure” (gauge pressure) produced by the hydraulic power unit (HPU) pumps on the surface.

It should be noted that the “absolute internal pressure” of the hydraulic fluid acting on actuators, operators and other control system components located on the seabed can be significantly higher than the surface gauge pressure (due to hydrostatic head of the control fluid in deepwater) but these components typically have the same “RWP” as the surface HPU NOTE Hydraulic controls equipment is outside the scope of this document, unless they contain or control well bore fluids. As described above, there are different definitions of “pressure rating”, “working pressure” and “RWP” between various types of equipment used within the same subsea system.

For applications in deepwater, external pressure can result in a significant reduction in the differential pressure for a given absolute internal pressure. Ignoring the benefits of external pressure can result in larger and difficult to produce equipment designs and potential overly conservative validation requirements. Inconsistency between “RWP” terminologies can also complicate equipment selection decision-making process. Stresses within a pressure vessel are primarily driven by the differential pressure acting on the vessel wall (internal pressure minus external pressure).

However, in some cases, stresses can also be affected by the absolute pressure and not simply by the differential pressure (for example, equipment containing trapped void spaces). While the presence of external pressure may reduce stresses due to the effects of internal pressure, it may not be on a “one-for- one” basis. Therefore, when selecting equipment, the designer cannot simply subtract the external pressure from the internal pressure to determine the required “RWP” for API 6A or API 17D equipment.API TR 17TR12 pdf download.API TR 17TR12:2015 pdf free download