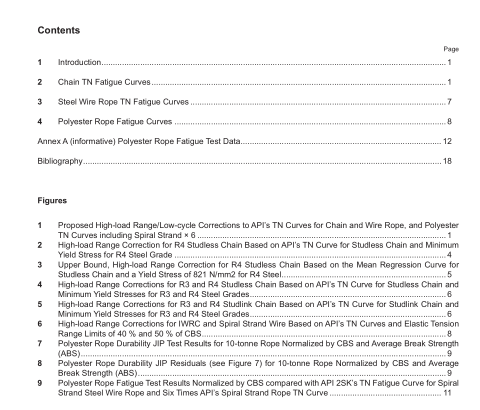

API TR 2FC-2:2020 pdf free download.Fatigue TN Curves for Chain, Wire, and Polyester Mooring Lines (Including Corrections for High-tension Ranges)

This report summarizes the derivation of high-load range, low-cycle corrections to API 2SK, Third Edition studlink and studless chain fatigue curves, and in this respect supplements the derivation of standard fatigue curves reported in API TR 2FC-1, First Edition. In addition, low-cycle, high-load range corrections to API 2SK’s independent wire rope core (IWRC) and spiral strand (SS) wire rope fatigue curves are proposed, and polyester rope fatigue data are reviewed and compared with the recommendations presently contained in API 2SM, API 2SK, and ISO 19901-7. The proposed corrections to API’s TN curves and the chain and polyester fatigue test data are shown in Figure 1. The lower part of the piecewise linear TN curves (in the log-log space) are the same as in API 2SK, while the upper part is the correction or change proposed.

Large tension ranges resulting from vortex induced motions of a Gulf of Mexico spar frst led to the identifcation of the need to add a correction for high-tension range, low-cycle fatigue damage to the existing fatigue curves contained in API 2SK, Appendix H. More recently, a “Cyclic Integrity Test (20-hurricane test)” consisting of 20,000 cycles between 15 % and 45 % of the ropes break strength has been proposed for polyester ropes. Consequently, it seems appropriate at this time to review existing fatigue curves and test data, and propose corrections for low- cycle, high-tension range fatigue damage.

2 Chain TN Fatigue Curves Equation (1) expresses API 2SK’s TN curves for chain mooring lines in tension as:

where

T is R divided by the catalog break strength (CBS) of oil rig quality (ORQ) chain of the same bar diameter;

R is the double amplitude tension range;

m is the slope of fatigue curve;

API 2SK, Section 6.2.1, normalizes the tension range, R, by the reference break strength (RBS) and states “For chain, RBS is taken as minimum breaking strength (MBS) of ORQ common chain link of the same size for ORQ, R3, R4, and R4S common or connecting links. Guidance on increase of chain diameter for corrosion and wear and its efect on fatigue life calculation are given in Section 7.6. For wire rope, RBS is the same as MBS.” API 2SK, Section 7.2, then defnes MBS as follows, “MBS is defned as the breaking strength guaranteed by the mooring component manufacturer. The minimum breaking strength of chain may be taken as the break test load (BTL).” To avoid introducing confusion and too many defnitions and abbreviations catalog break strength (CBS) is used herein. Note that for the term minimum break strength to be meaningful, the MBS value shall be associated with a defned probability of exceedance and for a constant probability that break strength is above the minimum value, the value of MBS shall decrease as the length of the mooring line increases.

The parameters of API 2SK’s chain TN curves are based on fatigue tests performed on studlink and studless chain links of ORQ, R3, and R4 steel grades, with nominal bar diameters between 2 in. (51 mm) and 4 in. (102 mm), in oxygenated saltwater [3] .

API 2SK’s chain fatigue parameters are summarized in Table 1.

Table 2 summarizes the minimum material properties and proof and break-test load requirements for studlink and studless chain for steel grades between ORQ and R5.

Figure 2 clearly illustrates that API’s TN curve is not conservative for high-tension ranges, as it predicts a fatigue life for R4 chain in excess of 100 cycles when the load range is approximately equal to the break strength of the chain, and ~10 cycles when the load range is approximately three times the chain’s break strength. That is, the dashed part of API’s TN curve, shown in Figure 2, should not be used in calculating fatigue damage, as it under- predicts fatigue damage.API TR 2FC-2 pdf download.API TR 2FC-2:2020 pdf free download