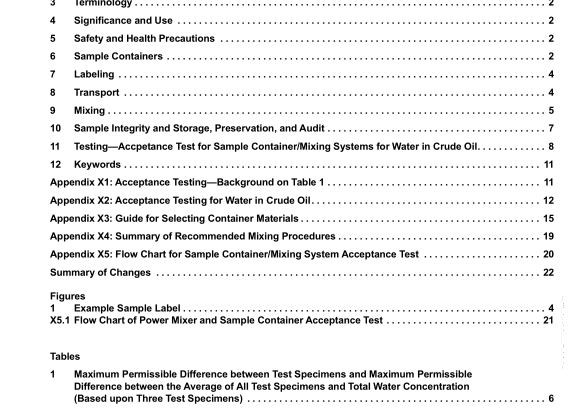

API MPMS 8.3:2019 pdf free download.Manual of Petroleum Measurement Standards Chapter 8.3 Standard Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

6.2.7 If the sample is likely to separate because it contains immiscible fluids (for example, water or sediment in oil), the containers should be designed to allow for homogenization while preventing the loss of any constituents that affect the representativeness of the sample and the accuracy of the analytical tests.

6.2.8 Containers should be made so as to avoid contamina- tion from external foreign material (for example, the ingress of water or other contaminants). When the sample contains immiscible fluids, care shall be taken to adequately homogenize the content so that any extracted sample is within the allowed repeatability of the bulk value of that property. Note that in the case of hydrocarbon and water, adequate mixing to determine water content is likely to irreversibly damage other properties of interest such as density.

6.2.9 Containers used with closed loop mixers may need a pressure/vacuum relief valve set so as not to exceed the design pressure of the container. A pressure gauge may also be incorporated.

6.2.10 Containers used with closed loop mixers for non- homogeneous fluids shall have a suction port at or near the bottom.

6.2.11 Constant pressure cylinders are referred to in Practice D3700, Practice D4057 (API MPMS Chapter 8.1), Practice D4177 (API MPMS Chapter 8.2), and Practice D8009 (API MPMS Chapter 8.5) discusses the merits of the constant pressure cylinder for the sampling of rail cars and the like. These cylinders are designed to allow spot or composite samples to be taken from a pressurized tank or pipeline at full line conditions and maintain the sample at those conditions until analyzed.

6.2.12 The laboratory container shall be selected such that its construction material does not affect sample compositional integrity and its volume and its dimensions are sufficient to allow for adequate mixing. In selecting the laboratory test container, take particular care in respect of the following

: 6.2.12.1 Liquids containing volatile materials, as loss by evaporation can occur;

6.2.12.2 Liquids suspected to contain sediment and/or water, as separation can occur;

6.2.12.3 Samples with potential wax deposition, as separa- tion can occur if a sufficient temperature is not maintained;

6.2.12.4 Samples of high viscosity and/or density, as both temperature and mixer placement may be affected to obtain the required homogenization; and

6.2.12.5 Make sure constituents are compatible with the container material (that is, mercury readily forms an amalgam with aluminum).

6.3 Container Volume:

6.3.1 A general rule is that both primary and intermediate containers should be large enough to hold the required sample size within 60 % to 80 % ofthe total capacity. This provides for thermal expansion.

6.3.2 The size of primary containers is determined from the sampling operation as described in Practices D4057 (API MPMS Chapter 8.1) and D4177 (API MPMS Chapter 8.2).

6.3.3 The size of intermediate containers should be as large as practical to minimize surface tension effects with due consideration given to storage space requirements, shipping rules and regulations, availability, and other practicalities.

6.3.4 Refer to API 8.2 for composite sample volume and the number of samples when using automatic sampling systems.

6.4 Container Material:

6.4.1 Sample containers are normally made of glass, metal, or plastic. Exercise care in the selection of container material as it could affect the test results obtained from the sample. Containers acceptable for samples to be tested immediately may not be acceptable for storage of sample.

6.4.2 Glass containers are suitable for many sample test and storage requirements. Clear glass bottles may be examined visually for cleanliness and allow for visual inspection of the sample for free water or solid impurities. Some petroleum samples are affected by exposure to sunlight or fluorescent lamp UV emissions ifclear glass is used. In these cases, brown glass bottles may afford the necessary protection. Care should be taken to ensure the necessary protection is provided when selecting a container.

6.4.3 Sample containers coated with tin shall have seams that have been soldered on the exterior surfaces with a flux of rosin cleaned in a suitable solvent. Such a flux is easily removed with gasoline, whereas many others are very difficult to remove. API MPMS 8.3 pdf download.API MPMS 8.3:2019 pdf free download