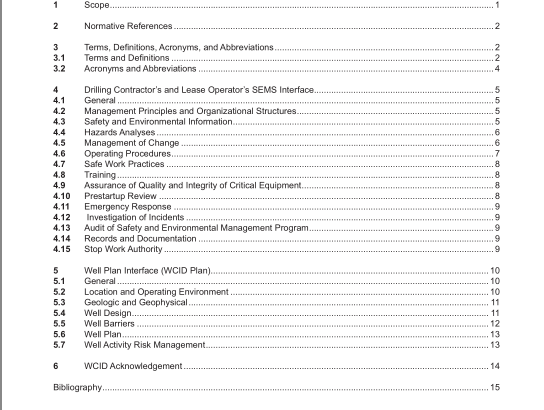

API 97L:2020 pdf free download.Onshore Well Construction Interface Document

4 Drilling Contractor’s and Lease Operator’s SEMS Interface 4.1 General The following sections identify key elements to be addressed to develop alignment between the lease operator and drilling contractor programs. This should be done by demonstrating agreement or by resolving diferences in their respective programs.

4.2 Management Principles and Organizational Structures

The interfaces between the drilling contractor’s and the lease operator’s SEMS should be agreed upon by both parties.

The roles and responsibilities of supervisory personnel at the wellsite and other appropriate personnel shall be agreed upon between the lease operator and drilling contractor. For simultaneous operations (SIMOPS), this should include all parties involved (i.e. operator, contractor, and third-party services), and an individual with the authority to oversee and coordinate activities on all involved parties shall be identifed. The interface of lease operator and drilling contractor principles and organizational structures should be developed in accordance with API 75L to promote safety and environmental protection.

Specifc management expectations should be defned. A WCID should not be a republication of each company’s SEMS; instead, it should be the interface between the two safety management systems intended to address well-specifc issues and to identify whose SEMS elements govern which activities. The intention of this document is to provide a mechanism for the lease operator and the drilling contractor to demonstrate agreement or resolve diferences between each company’s SEMS elements. The WCID should include the drilling contractor’s rig-specifc operating guidelines and its site-specifc assessment of critical well activities (e.g. blowout preventer [BOP] operations, shut-in procedures, etc.). The drilling contractor and lease operator should specify the position(s) responsible for the safe and efcient operation of the rig in accordance with applicable regulations, including emergency situations.

This includes the establishment of procedures for both internal and external communications of safety and environmental information. The description or link should include the following:

a) drilling contractor’s and lease operator’s key ofce-based personnel;

b) drilling contractor’s and lease operator’s key wellsite-based personnel.

The WCID should establish the exchange and alignment of safety and environmental management information prior to commencing work (see Section 5).

4.3 Safety and Environmental Information

Safety and environmental information for the rig and third-party equipment should be agreed upon by all parties involved.

The rig-specifc operating guidelines provide a basis for implementing SEMS elements. Rig description and supporting information can include mudfow management equipment (i.e. mud gas separators, diverter system, etc.). Equipment required to maintain and monitor barriers can include alarm systems (gas detectors, pit volume totalizer [PVT], fow meters) and well control systems. Third-party equipment interfaces with the rig systems that may need to be addressed include water, rig air, and electrical power. For SIMOPS, the possibility that the functionality or operability of critical equipment or systems can be compromised should be considered.

4.4 Hazards Analyses

The lease operator and the drilling contractor should each have defned risk management processes. The following examples typically govern the processes.

a) For hazards analyses associated with the well plan or well construction, the lease operator’s risk management process applies. The drilling contractor is included in the process.

b) For hazards analyses associated with the rig operation and capability of the rig, the drilling contractor’s risk management process applies. The lease operator is included in the process.

c) For hazards analyses associated with SIMOPS, the lease operator’s risk management process applies. The drilling contractor and third-party services are included in the process.

d) For job safety analysis (JSA) at the operations/task level, the drilling contractor’s process applies in most cases.

4.5 Management of Change

The responsibilities for initiating and leading MOC processes in common situations shall be established. The level of approvals required should be appropriate for the changes. The responsibilities for the MOC process regarding changes to well design, equipment (including third party), procedures, personnel, materials, operating conditions, etc. are shown in the following.

a) Lease operator shall notify the drilling contractor of a change in well design/well plan that afects safety- critical well construction components or processes. The lease operator MOC process applies, and the drilling contractor shall be consulted in the process and may participate in the associated hazard analysis.

— Lease operator should involve the drilling contractor for changes to the well plan that require regulatory approval or internal lease operator approval.API 97L pdf download.API 97L:2020 pdf free download