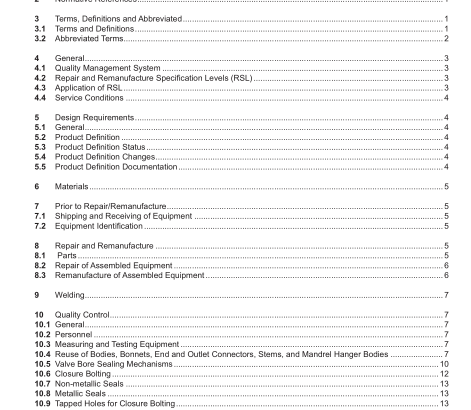

API St 6AR:2019 pdf free download.Repair and Remanufacture of Wellheadand Tree Equipment

4.4 Service Conditions

The API 6A service conditions shall apply to equipment that is repaired/remanufactured to this standard.

NOTE The service conditions include pressure ratings, temperature ratings, and material class ratings.

5 Design Requirements

5.1 General

A documented procedure to plan and control the product defnition of the repaired or remanufactured parts,used or reused parts, and new equipment shall be maintained by the organization performing the repair or remanufacture.

5.2 Product Defnition

Product defnition shall conform to API 18LCM, Section 5.3.1.2, including any additional design verifcation and validation requirements per API 6A for the product in repair or remanufacture.

NOTE Design validation may be done by an organization other than the repairer/remanufacturer.

5.3 Product Defnition Status

If the product defnition cannot be established from the markings on the equipment and records that are traceable to those markings, the equipment shall not fall within the scope of this document and cannot be repaired/remanufactured to the requirements of this standard.

5.4 Product Defnition Changes

When repair or remanufacture of the product impacts the product defnition and the performance established by the original technical specifcation, the new product defnition shall be developed in conformance with 5.2. The changes to the product defnition shall conform to the requirements defned in API 18LCM, Section 6.

NOTE Changes to product defnition can impact requirements for repair/remanufacture activities.

5.5 Product Defnition Documentation

Records of product defnition shall include the following:

― design inputs, including user/purchaser requirements;

― design outputs, including drawings and relevant acceptance criteria;

― evidence of design review and verifcation; and

― evidence of design validation.

Records of product defnition shall be maintained by the repairer/remanufacturer for 10 years after repair or remanufacture.

6 Materials

For RSL 1, RSL 2, RSL 3, and RSL 4, the materials shall conform to the requirements of API 6A for the applicable PSL corresponding to the RSL to which the equipment is being repaired/remanufactured.

7 Prior to Repair/Remanufacture

7.1 Shipping and Receiving of Equipment

Prior to shipping, the following shall be completed:

― All pressure has been released.

― Hazardous materials have been removed.

― A safety warning has been issued if a hazard is present.

― A check for NORM in compliance with the applicable local regulations (region/state/country/province) has been performed.

NOTE Equipment containing NORM may require special handling and cleaning procedures per applicable regulatory requirements.

7.2? Equipment? Identifcation

The owner of the equipment shall document the following information prior to shipping the equipment to the repairer/remanufacturer. Upon receiving the equipment and documentation, the repairer/remanufacturer shall verify and keep the following information in the repairer/remanufacturer quality control record:

― original manufacturer;

― part number and revision level, if applicable;

― size and working pressure;

― PSL, PR, temperature rating, material class, and previous RSL, as applicable;

― serial number and any other traceable information, as applicable;

― any additional comments deemed important by the owner of the equipment regarding the general condition of the equipment.

8 Repair and Remanufacture

8.1 Parts

Used, reused, repaired, and remanufactured parts shall conform to Section 10.

New parts shall conform to API 6A.

Repair and remanufacture shall not include replacement of the body.

Repair welding of bullplugs, valve removal plugs, and back-pressure valves shall not be permitted.

8.2? Repair? of? Assembled? Equipment

Repair of equipment shall not include remanufacturing (machining, welding, or heat treating) of pressurecontaining parts and pressure-controlling parts.

Repair of equipment shall require the following:

a) Disassembly and cleaning shall conform to the repairer’s/remanufacturer’s documented requirements.

Control procedures shall be included to segregate or identify components of each assembly to avoid mixing or mismatching of parts.

For RSL 2, RSL 3, and RSL 4, disassembly shall be required to the extent necessary for complete evaluation of pressure-containing and pressure-controlling parts.

NOTE For RSL 1, disassembly may be required to the extent necessary to evaluate the equipment for conformance with the requirements of this standard.

b) Visual inspection shall be performed in conformance with documented requirements, which include acceptance criteria. Results of the inspection shall be documented and retained.API St 6AR pdf download.API St 6AR:2019 pdf free download