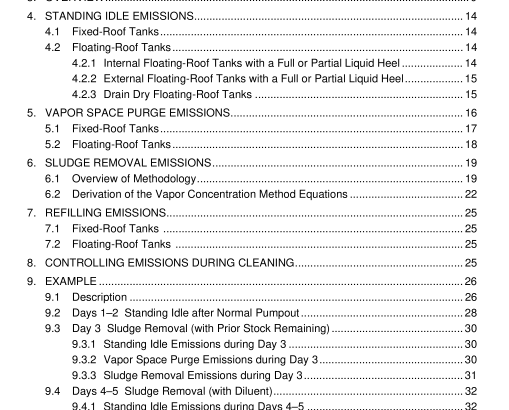

API TR 2568:2007 pdf free download.Evaporative Loss from the Cleaning of Storage Tanks

3) Removal From Inside the Tank.

a) Sludge Removal: Workers enter the tank to remove any remaining sludge. i. Water, fuel oil or approved chemicals may be used to wash down the material to be removed.

b) Vapor Space Purge: After any period (such as overnight) during which removal activities have ceased, forced ventilation is resumed prior to workers reentering the tank. Although this stage involves workers entering the tank, the potential scenarios from an emissions perspective are the same as for removal activities from outside an opened tank:

– Sludge removal (with forced ventilation)

– Standing Idle (without forced ventilation)

– Vapor Space Purge (after a period of standing idle without forced ventilation) The primary change in condition continues to be the nature of the exposed surface, and thus the properties of the materials being removed. For purposes of estimating emissions, then, tank cleaning may be characterized as comprising the following steps:

a) Normal Pumpout: As much stock liquid as possible is pumped out through the tank outlet in the normal manner (i.e., until the liquid level has dropped below the open end of the outlet line, and no more liquid moves through the outlet). [If the tank has a floating roof, the floating roof will have landed on its legs and its vacuum breaker vent will have opened, causing air to be drawn into the space beneath the floating roof. Prior to emptying the tank for cleaning, the floating roof legs are usually placed in the high leg position (typically about 6 ft) to maximize the space available for workmen under the floating roof.] As the liquid level drops during normal pumpout, flow of air through the tank vents is from outside the tank to inside the tank. Given this inward direction of air flow, it is assumed that no emissions occur during normal pumpout.

b) Standing Idle: The tank may remain in the condition resulting from normal pumpout for some period of time until the next step begins. This condition will typically involve a full or partial heel of stock liquid remaining in the bottom of the tank. The defining characteristics of the standing idle condition are: – volatile material, capable of generating vapors, remains in the tank (as a full or partial liquid heel, or as clingage on the tank bottom), – the height of the vapor space is reasonably constant (change is limited to stripping of the liquid heel, or pumping in of diluent) during the period in question, and – there is no forced ventilation of the vapor space (i.e., no eductors, fans, or blowers are engaged in expelling vapors from the tank). During a standing idle period, vapors are generated inside the tank by evaporation of the remaining volatile material. The diurnal temperature cycle causes expansion and contraction of the air/hydrocarbon mixture (i.e., vapors) in the tank, thereby causing some of these vapors to be expelled from the tank. For an external floating-roof tank, these vapor losses may be further driven by wind action. c) Vapor Space Purge: When eductors, fans, or blowers are started up, either at the top of the tank or at a shell manhole, cleanout fitting or other shell fitting, the first air change is deemed to expel those vapors that remain from the prior stage of the tank cleaning process. This constitutes a purge of vapors from the tank. Emissions associated with subsequent air changes are accounted for under sludge removal.

A vapor space purge will occur each time that ventilation commences after a period of standing idle without ventilation.API TR 2568 pdf download.API TR 2568:2007 pdf free download