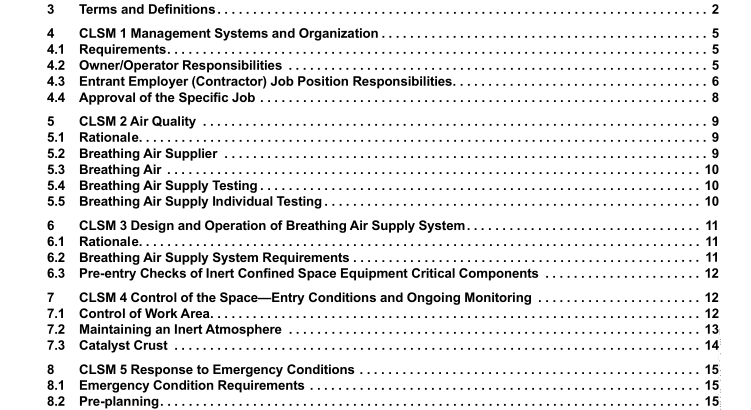

API RP 2217A:2017 pdf free download.Safe Work in Inert Confined Spaces in the Petroleum and Petrochemical Industries

6 CLSM 3 Design and Operation of Breathing Air Supply System

6.1 Rationale Inert entry equipment shall be designed and maintained to provide critical redundancy, automatic back-up, instrumentation and alarms, communication, and delivery means (i.e. air supply racks, hoses, umbilical cords, helmets) to minimize human error (especially in an emergency situation where personnel are more likely to panic).

6.2 Breathing Air Supply System Requirements The design of the breathing air equipment must be a life support system and shall satisfy the following requirements.

a) Separate primary and secondary air supplies (i.e. racks) connected to an instrument panel (typically called the air console) to monitor the air supply source pressure and use of air shall be provided. Valves shall be secured in the open position when in use. Any branches that may be used for air testing or blow down of accumulated condensate must be capped when not in use. The breathing air system shall include audible alarms set not lower than 35 bar/ 500 psi for the primary and secondary supplies.

b) A separate air cylinder (minimum of one hour supply) typically located at the entry opening and pressurized hose line (typically called an EEL) shall be provided for each person under helmet. Additional cylinders shall be staged and available if necessary.

c) An egress air bottle (typically called a five-minute egress) shall be attached to the harness of each person under helmet.

d) An integrated helmet/respirator assembly (sometimes called a clamshell) or suit that is sufficiently secure to prevent user-attempted removal during a panic situation shall be provided. Note: A typical soft-faced respirator used with breathing air delivery systems is unacceptable because persons in distress will instinctively remove the face piece and expose themselves to an inert environment, which will result in almost certain death.

e) A helmet assembly that includes primary (in-use) and secondary (backup) air regulators that operate independently of one another. Positive pressure maintained at the face piece shall be provided. The secondary shall open automatically if there is loss of pressure from the primary breathing air supply rack.

f) A hands-free communication system shall be provided that links to all personnel under helmet and the air console technician and the attendant. Communication monitoring by the air console technician shall not be discontinued while a person is inside the inert confined space. An alternative way of alerting a person in the vessel to evacuate in case of loss of communication shall be provided and known by the people involved in the entry operation, including the confined space attendant.

g) An umbilical cord (crushproof sheathing) containing primary and secondary air supply hoses, communication cable(s), video cable (if present), and a steel safety cable shall be provided, including a means to manage the length of the cord (typically a reel) to prevent kinking and unnecessary exposure to conditions.

h) Video capability (either integrated into the helmet or separate in the space) shall be provided to ensure visual contact with in vessel crew. (Note: This is not necessary if reasonable line of sight is maintained between the attendant(s) and entrant(s).

i) The breathing air console operator shall not switch or open new air cylinders while personnel are under helmet in the vessel.

NOTE Redundant Design Requirement 3.1 may not completely protect a loss of air supply since changing air cylinders may cause unforeseen ice, scale, or other debris to become dislodged and plug airline components.

j) If new air cylinders must be opened with entrant(s) under helmet while in the vessel, entrant(s) shall immediately be removed from inerted environment. A new breathing air system check shall be performed by a qualified person prior to use of new air cylinder line up.

6.3 Pre-entry

Checks of Inert Confined Space Equipment Critical Components

a) Critical components shall be tested and or inspected by a qualified person (typically assigned by the entrant employer) just prior to entry to ensure required conditions are satisfied. Records of such testing or inspections shall be maintained on a daily checklist or equivalent for a period as required by the applicable confined space program.API RP 2217A pdf download.API RP 2217A:2017 pdf free download