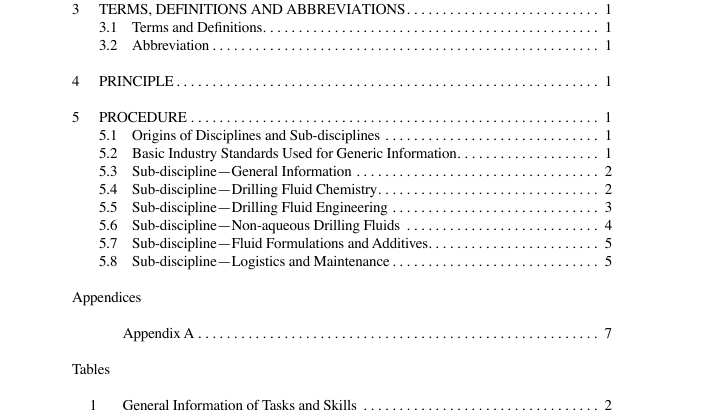

API RP 13L:2003 pdf free download.Recommended Practice for Training and Qualification of Drilling Fluid Technologists

1 Scope This standard is a written summary of basic training and knowledge that an employee or contractor shall possess to be identiÞed as a drilling ßuids technologist. Levels of under- standing have been generally outlined, but not totally deÞned.

3 Terms, Definitions and Abbreviations

3.1 TERMS AND DEFINITIONS

3.1.1 breadth: The basic knowledge common to all areas of drilling ßuids technology needed by all drilling ßuids tech- nologists to demonstrate minimum competency.

3.1.2 depth: The knowledge acquired by all drilling ßuids technologists following 4 Ð 6 years of practical experience.

3.1.3 drilling fluids engineer: A drilling ßuids technol- ogist with an engineering degree from an accredited university.

3.1.4 drilling fluids technician: An individual skilled in the art of testing drilling ßuids in the Þeld or the laboratory.

3.1.5 drilling fluids technologist: Individual with spe- cialized knowledge of the application of drilling ßuids during the drilling operation.

3.1.6 senior drilling fluids technologist/engineer: A drilling ßuid technologist or engineer who by training and experience has advanced knowledge of drilling ßuids, drilling ßuid chemistry, and their varied applications.

3.2 ABBREVIATION

API American Petroleum Institute

HTHP High temperature, high pressure

MBT Methylene blue test

PV Plastic viscosity in cP (1 cP = 1 mPa*s)

YP Yield point in Pa

4 Principle

This document is a recommended practice (RP) and seeks to formalize the speciÞc knowledge base, professional skills, and application skills needed to ensure the competency and professionalism of individuals working in the drilling ßuids industry. Drilling ßuids technologists should use this RP as an outline to self-determine any gaps in learning and seek to improve their skills. A company contracting the service of a drilling ßuids technologist should use this recommended practice as a checklist of knowledge that a technologist should be able to demonstrate proÞciency in applying.

5 Procedure

5.1 ORIGINS OF DISCIPLINES AND SUB- DISCIPLINES The drilling ßuids disciplines and sub-disciplines were developed from a review of the typical curricula followed by drilling ßuids service companies in their basic mud school. The topics as listed in Appendix A were used as a framework for developing the guidelines that form the normative portion of this standard. Each sub-discipline was divided into appro- priate tasks and those tasks were assigned breath of knowl- edge statements needed to obtain minimum competency. The drilling ßuid technologist discipline is broken into six sub- disciplines and each sub-discipline is described by tasks and speciÞc skills to demonstrate proÞciency and knowledge in that task. For ease of reading, the tasks and skill set are placed in a table format.

5.2 BASIC INDUSTRY STANDARDS USED FOR GENERIC INFORMATION API Spec 13A and ISO 13500, Specifications for Drilling Fluid Materials, provide speciÞcations for drilling ßuid mate- rial. Two documents cover the Þeld testing procedures for tests included on the drilling mud report form. These are API RP 13B-1 or ISO 10414-1, Standard Procedure for Field Testing of Water-based Drilling Fluids , and API RP 13B-2 or ISO 10414, Standard Procedure for Field Testing of Oil- based Drilling Fluids .API RP 13L pdf download.API RP 13L:2003 pdf free download