API 2540:2004 pdf free download.API2540 Liquid Volume Correction User Program (ROC300-Series and FloBoss™ 407 Flow Managers) (ROCLINK™ for DOS Configuration Software)

This document serves as a user manual for the API2540 Liquid Volume Correction User Program (QER 03Q008), intended for use with the ROC300-series of Remote Operation Controllers (ROCs) with a FlashPAC, version 2.12 or greater, and FloBoss™ 407 Flow Manager, version 1.08 or greater.

This manual describes how to download, configure, and monitor the program. The user program is accessed using ROCLINK™ for DOS configuration software version 2.23. The configuration software uses an IBM-compatible computer and Windows ® Operating System. For information on use of the API2540 program with ROCLINK 800 configuration software, refer to user manual Form A6167.

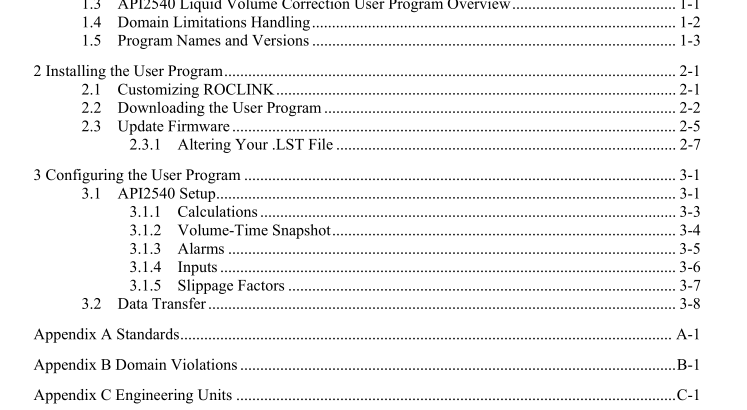

1.2 Organization of this Manual In this manual, the sections are arranged to provide information in the order in which it is required for firsttime users. Once you become familiar with the procedures, and the software is running in a ROC or FloBoss 407, use the manual as a reference tool.

The manual is organized into the following major sections: Section

1 Getting Started Section

2 Installing the User Program Section

3 Configuring the User Program Appendix A Standards Appendix B Domain Violations Appendix C Engineering Units

This manual assumes that the user is familiar with the ROC300-series and FloBoss 407 units and their configuration. For additional information, refer to the:

Type ROC306/ROC312 Remote Operations Controller Instruction Manual (Form A4630).

Type ROC364 Remote Operations Controller Instruction Manual (Form A4193).

FloBoss 407 Flow Manager Instruction Manual (Form A6013).

RL101 ROCLINK Configuration Software User Manual (Form A6051).

? NOTE: “ROC” is used in this manual to stand for all ROC and FloBoss devices.

1.3 API2540 Liquid Volume Correction User Program Overview

The Liquid Correction Program is designed for the ROC300-series units equipped with FlashPACs and the FloBoss 407. The Liquid Correction Program corrects the measured flow of crude oils, oil generalized products, LPG, and water by converting values to standard temperature and pressure levels. The Liquid Correction Program monitors the current flow rate, temperature, and pressure, and to calculate a corrected flow value for standard conditions based upon density value, sediment, and water percent value, vapor pressure, and the meter slippage factor.

The Liquid Correction Program accumulates the volume of the flowing fluid and can be configured to perform calculations for up to three different flows in the ROC306 and ROC312, five flows in the ROC364, or four flows in the FloBoss 407. The Liquid Correction Program tracks two accumulated volumes for each flow. One accumulation is the volume since contract hour or last manual reset and the second accumulation is a running total that rolls over at 9,999,999. At contract hour or manual reset, flow and minutes today are transferred to flow and minutes yesterday.

The Liquid Correction Program supports the following liquids:

Crude oil.

Generalized oil products (jet fuel, diesel, oil, and gasoline).

LPG (Liquefied Petroleum Gas).

Water.

The Liquid Correction Program supports the following standards:

API2540 Tables 5A, 5B, 6A, 6B, 34, 53, 53A, 53B, 54, API21, API5, AGA3/1992 and was developed according to API/ANSI/AGA standards. Refer to Appendix A for a list of all applicable standards.

The Liquid Correction Program supports the following types of inputs:

Pulse (mass or volume).

Analog Flow (mass or volume).

Analog Differential Pressure (DP).

Density.

Vapor Pressure.

Water and Sediments.

An uncorrected flow can be determined by one of the following inputs:

Pulse Input (such as from a turbine).

Analog Input (such as from a Vortex or MicroMotion).

Differential Orifice Metering (flange taps only).API 2540 pdf download.API 2540:2004 pdf free download